Microcapsules enable self-lubricating plastics

Plastic components with longer service life

23 percent of global energy consumption can be attributed to friction losses. Components with reduced friction therefore represent an important contribution to conserving resources and achieving climate protection targets. In the case of plastics, reduced friction can also reduce microplastics in the environment. With the development of microcapsules filled with liquid lubricants for plastics, the Potsdam Fraunhofer Institute for Applied Polymer Research IAP and the Plastics Center SKZ in Würzburg are supporting these goals. Their self-lubricating plastics achieve up to 85 percent less wear. Since March 2021, the successful research project has been continued for two years.

Self-lubricating plastics are expected to drastically reduce component wear in the future.

asharkyu, Shutterstock

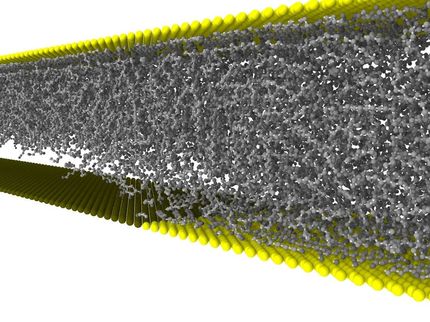

Whether it's sliding doors, laminate, plastic gears or other moving components – there is a variety of applications where materials are subject to friction. Plastics manufacturers are therefore sometimes incorporating solid lubricants into plastics to reduce component wear. However, there are only a relatively small number of solid lubricants suitable for plastics processing. In contrast, there is a much wider range of liquid lubricants, some of which are more effective. In a cooperative effort, the two research institutes have succeeded in encapsulating liquid lubricants in such a way that they can be incorporated into polymers as functional substances and later develop all the advantages of a liquid lubricant in the component.

85 percent less wear

"We managed to incorporate Fraunhofer IAP‘s microcapsules filled with liquid lubricant into thermoplastics using a twin-screw extruder. The challenging task was to mix the microcapsules with thermoplastics under high temperatures without damaging the capsules. Only when friction occurs in the final component the capsules should break and release the lubricant. This allows the component to lubricate itself automatically", explains Moritz Grünewald, researcher in the Materials Development Group at the SKZ Plastics Center. "Our friction and wear tests showed a reduction in wear of up to 85 percent on plastic-steel pairings. Thus, components last significantly longer and generate less microplastic."

Based on these results, the material system is being optimized further for potential applications. The development is now focusing on improved mechanical and thermal properties of the self-lubricating plastics.

Reinforcement of self-lubricating plastics

The additional use of reinforcing materials such as fibers is intended to make the self-lubricating plastics more mechanically stable. In the project, the researchers investigate, which type of fiber is best suited for this purpose and how the microcapsules can be optimally bonded to the plastic matrix. In addition, the capsules are also to be incorporated into higher-melting plastics in order to further widen the technical application possibilities. To this end, even more stable capsule wall materials are being developed in close cooperation between the project partners. "The main challenge is that the capsules should not break until they come into frictional contact in the final application. However, if we introduce additional fibers and increase the temperatures, the stresses on the capsules increases during the mixing process," explains Dr. Alexandra Latnikova, microencapsulation specialist at Fraunhofer IAP. Her team develops the micorcapsule systems.

Great interest from the plastics industry

Numerous inquiries from industry highlight the need for novel plastics with optimized friction and wear properties. Microencapsulation technology has major advantages for companies in this regard: the wide range of liquid and advanced lubricants can now be used as internal lubricants with on-demand release properties. The project is accompanied by a committee that includes companies from all sectors of the plastics industry, lubricant manufacturers and microencapsulators. The project is open to further partners.

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.