Plasma acceleration: It’s all in the mix

A pinch of nitrogen and artificial intelligence are moving laser plasma acceleration a big step closer to practical applications

Advertisement

The LUX team at DESY is celebrating not just one but two milestones in the development of innovative plasma accelerators. The scientists from the University of Hamburg and DESY used their accelerator to test a technique that allows the energy distribution of the electron beams produced to be kept particularly narrow. They also used artificial intelligence to allow the accelerator to optimise its own operation. The scientists are reporting their experiments in two papers published shortly after one another in the journal Physical Review Letters. “It’s fantastic to see the speed with which the new technology of plasma acceleration is reaching a level of maturity where it can be used in a wide range of applications,” congratulates Wim Leemans, Director of the Accelerator Division at DESY.

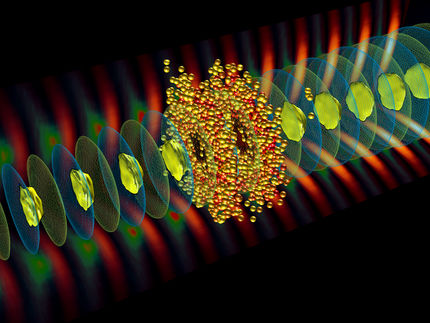

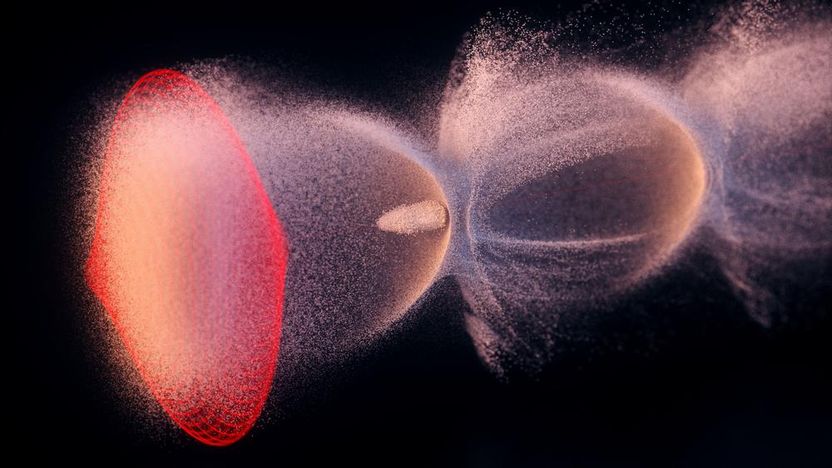

In laser plasma acceleration, an intense laser pulse (red) in an ionised gas drives a bubble-shaped plasma wave consisting of electrons (white). An electron bunch (centre) riding this wave like a surfer is thus accelerated to high energies over shortest distances. The rendering is based on real simulation data from the LUX experiment.

DESY/SciComLab

Plasma acceleration is an innovative technology that is giving rise to a new generation of particle accelerators which are not only remarkably compact but also extremely versatile. The aim is to make the accelerated electrons available for applications in various different fields of industry, science and medicine.

The acceleration takes place in a tiny channel, just a few millimetres long, filled with an ionised gas called a plasma. An intense laser pulse generates a wave within the channel, which can capture and accelerate electrons from the plasma. “Like a surfer, the electrons are carried along by the plasma wave, which accelerates them to high energies,” explains Manuel Kirchen, lead author of one of the papers. “Using this technique, plasma accelerators are able to achieve accelerations that are up to a thousand times higher than those of the most powerful machines in use today,” adds Sören Jalas, author of the second paper.

However, this compactness is both a curse and a blessing: since the acceleration process is concentrated in a tiny space that is up to 1000 times smaller than conventional, large-scale machines, the acceleration takes place under truly extreme conditions. Therefore, a number of challenges still have to be overcome before the new technology is ready to go into series production.

The research team led by Andreas Maier, an accelerator physicist at DESY, has now reached two critical milestones at the LUX test facility – jointly operated by DESY and the University of Hamburg: they have found a way of significantly reducing the energy distribution of the accelerated electron bunches – one of the most essential properties for many potential applications. To do this, they programmed a self-learning autopilot for the accelerator, which automatically optimises LUX for maximum performance.

The group conducted its experiments using a new type of plasma cell, specially developed for the purpose, whose plasma channel is divided into two regions. The plasma is generated from a mixture of hydrogen and nitrogen in the front part of the cell, which is about 10 millimetres long, while the region behind it is filled with pure hydrogen. As a result, the researchers were able to obtain the electrons for their particle bunch from the front part of the plasma cell, which were then accelerated over the entire rear section of the cell. “Being more tightly bound, the electrons in the nitrogen are released a little later, and that makes them ideal for being accelerated by the plasma wave,” explains Manuel Kirchen. The electron bunch also absorbs energy from the plasma wave, changing the shape of the wave. “We were able to take advantage of this effect and adjust the shape of the wave so that the electrons reach the same energy regardless of their position along the wave,” adds Kirchen.

Based on this recipe for achieving high electron beam quality, the team then scored a second research success: Sören Jalas and his colleagues were able to use artificial intelligence (IA) to modify an algorithm that controls and optimises the complex system of the plasma accelerator. To do so, the scientists provided the algorithm with a functional model of the plasma accelerator and a set of adjustable parameters, which the algorithm then optimised on its own. Essentially, the system modified five main parameters, including the concentration and density of the gases and the energy and focus of the laser, and used the resulting measurements to search for an operating point at which the electron beam has the optimum quality. “In the course of its balancing act in 5-dimensional space, the algorithm was constantly learning and very quickly refined the model of the accelerator further and further,” says Jalas. “The AI takes about an hour to find a stable optimum operating point for the accelerator; by comparison, we estimate that human beings would need over a week.”

A further advantage is that all the parameters and measured variables continue to train the accelerator’s AI model, making the optimisation process faster, more systematic and more targeted. “The latest progress at LUX means we are well on the way to trying out initial applications for test purposes,” explains Andreas Maier, who is in charge of developing lasers for plasma accelerators at DESY. “Ultimately, we also want to use plasma-accelerated electron bunches to operate a free-electron laser.”

The experiments were conducted by researchers from the Center for Free-Electron Laser Science (CFEL), a collaboration between DESY, the University of Hamburg and the Max Planck Society, as well as a colleague from the Lawrence Berkeley Laboratory in California.

Original publication

Manuel Kirchen, Sören Jalas, Philipp Messner, Paul Winkler, Timo Eichner, Lars Hübner, Thomas Hülsenbusch, Laurids Jeppe, Trupen Parikh, Matthias Schnepp, and Andreas R. Maier; "Optimal beam loading in a laser-plasma accelerator"; Phys. Rev. Lett. 126, 174801 (2021).

Sören Jalas, Manuel Kirchen, Philipp Messner, Paul Winkler, Lars Hübner, Julian Dirkwinkel, Matthias Schnepp, Remi Lehe, and Andreas R. Maier; "Bayesian optimization of a laser-plasma accelerator"; Phys. Rev. Lett. 126, 104801 (2021).