Understanding Interfaces of Hybrid Materials with Machine Learning

A design principle for the self-assembly of functionalized molecules devised

Using machine learning methods, researchers at TU Graz can predict the structure formation of functionalized molecules at the interfaces of hybrid materials. Now they have also succeeded in looking behind the driving forces of this structure formation.

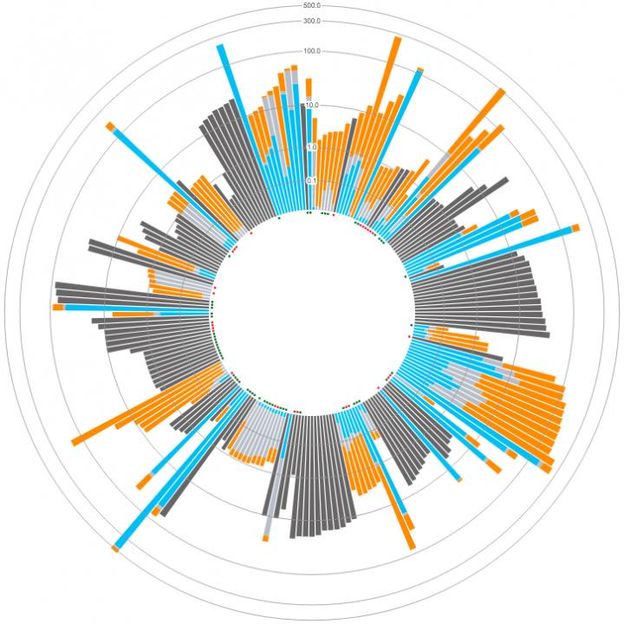

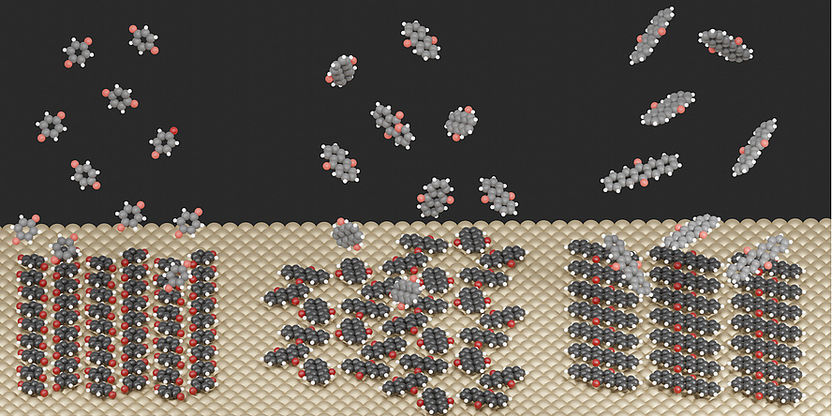

The illustration shows the strongly different surface structures that form for the three molecules studied when adsorbed on a metal surface.

© Jeindl - TU Graz

The production of nanomaterials involves self-assembly processes of functionalized (organic) molecules on inorganic surfaces. This combination of organic and inorganic components is essential for applications in organic electronics and other areas of nanotechnology.

Until now, certain desired surface properties were often achieved on a trial-and-error basis. Molecules were chemically modified until the best result for the desired surface property was found. However, the processes controlling the self-assembly of molecules at interfaces are so complex that small molecular changes can lead to completely different motifs. Physicists from TU Graz explain this unexpected structure formation in a study published in the journal ACS Nano. For this purpose, the researchers studied quinoid compounds on a silver surface. First author Andreas Jeindl from the Institute of Solid State Physics explains: "Naively, one might expect molecules with slightly different sizes but the same functionalization to form similar motifs. In striking contrast, our joint theoretical and experimental study shows that quinones can form diverse structures. Despite constant initial conditions, the formation of these structures cannot be predicted and planned without detailed knowledge of the relevant interactions."

Three opposing driving forces

The researchers in Graz, together with a team from the FSU Jena, have now started to break down this unpredictability. They found that the structure formation is the result of a trade-off between three opposing driving forces: The interaction between molecules and the metal attempts to force all molecules into the same orientation, while the interaction between molecules sometimes favours different orientations. The geometric shapes of the molecules then act as a third factor, preventing or only partially permitting certain interactions.

Based on this, they were able to establish a design principle with which the structures that form at the interfaces, and subsequently their properties, can be predicted – at least for a first class of molecules. An essential role is played by a search algorithm (SAMPLE) based on machine learning. Jeindl elaborates: "We were able to show in this publication that the structures predicted by our algorithm are in excellent agreement with experimental characterizations of organic-inorganic interfaces – both in how the molecules orient themselves on the surface and in how the motifs repeat on the surface. Moreover, our analysis, for the first time, allowed a detailed and quantitative break down of the driving forces, not only of the experimentally formed structures, but de facto of all conceivable structures. This is an important look behind-the-scenes of structure formation."

Interfacial properties with modular building blocks

The non-intuitive interplay of similarly important interaction mechanisms remains a challenge for the design of functional interfaces. With a detailed investigation of all the driving forces, however, the physicists at TU Graz are nevertheless able to devise a design principle for the self-assembly of functionalized molecules for a given class of molecules. Once there are enough analyses for different classes of molecules, the right molecules for the desired interfacial properties can be easily assembled on the computer from modular building blocks.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Mirtazapine

Breakthrough_bleeding

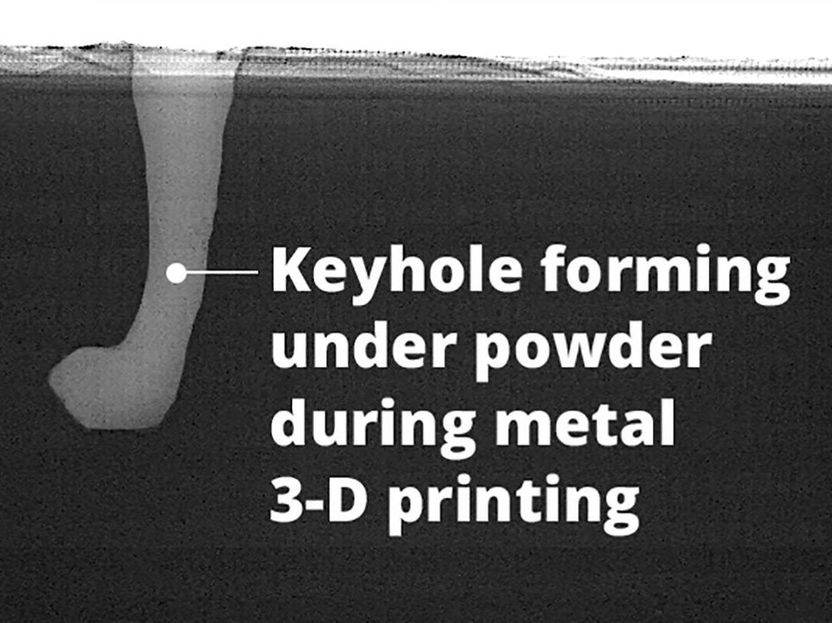

Patent filings in 3D printing grew eight times faster than average of all technologies in last decade

Causes for defects in 3D printing - Paving way for better results

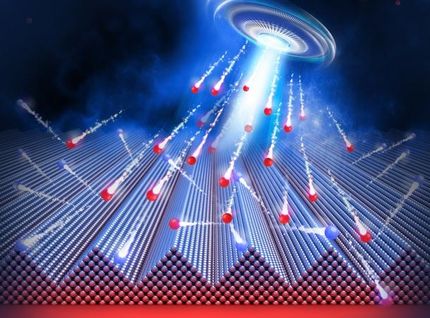

Unique material could unlock new functionality in semiconductors - New ferroelectric material can be manipulated using light in previously impossible ways

Diphosphines

Micromeritics Ltd - Hexton, United Kingdom

Rubber_Elasticity