Mysterious organic scum boosts chemical reaction efficiency, may reduce chemical waste

Chemical manufacturers frequently use toxic solvents such as alcohols and benzene to make products like pharmaceuticals and plastics. Researchers are examining a previously overlooked and misunderstood phenomenon in the chemical reactions used to make these products. This discovery brings a new fundamental understanding of catalytic chemistry and a steppingstone to practical applications that could someday make chemical manufacturing less wasteful and more environmentally sound.

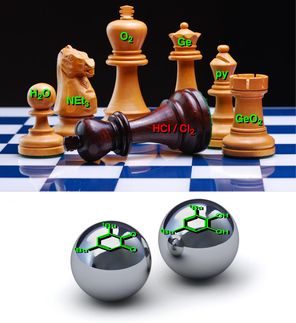

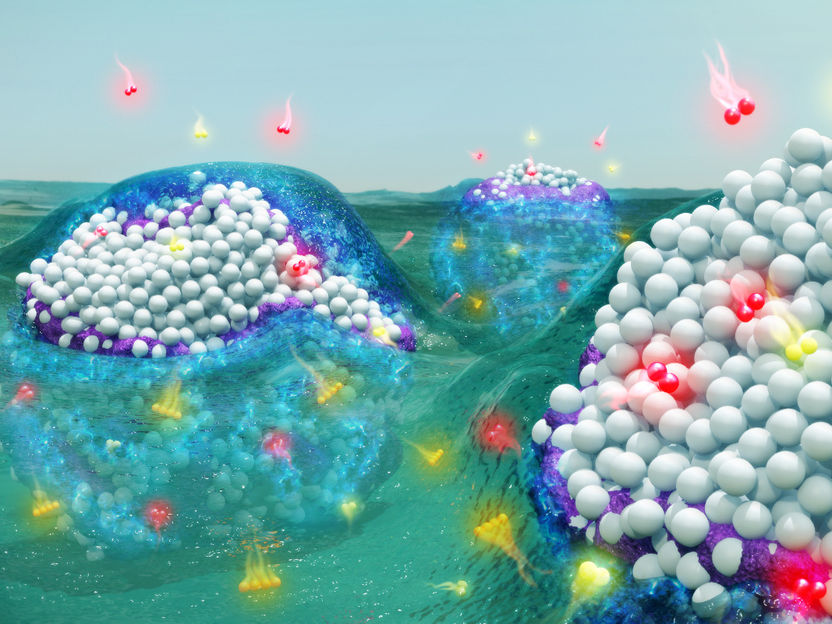

Illinois researchers are part of multi-institutional team that found that solvents spontaneously react with metal nanoparticles to form reactive complexes that can improve catalyst performance and simultaneously reduce the environmental impact of chemical manufacturing. Reprinted with permission from D. Flaherty et al., Science 371:6529 (2021).

Graphic courtesy Alex Jerez, Imaging Technology Group - Beckman Institute.

The study led by University of Illinois Urbana-Champaign researcher David Flaherty, University of Minnesota, Twin Cities researcher Matthew Neurock and Virginia Tech researcher Ayman Karim is published in the journal Science.

Combining solvents and metal nanoparticles accelerates many chemical reactions and helps maximize yield and profit margins for the chemical industry. However, many solvents are toxic and difficult to safely dispose, the researchers said. Water works, too, but it is not nearly as efficient or reliable as organic solvents. The reason for the difference was thought to be the limited solubility of some reactants in water. However, multiple irregularities in experimental data have led the team to realize the reasons for these differences were not fully understood.

To better understand the process, the team ran experiments to analyze the reduction of oxygen to hydrogen peroxide - one set using water, another with methanol, and others with water and methanol mixtures. All experiments used palladium nanoparticles.

"In experiments with methanol, we observed spontaneous decomposition of the solvent that leaves an organic residue, or scum, on the surface of the nanoparticles," said Flaherty, a professor of chemical and biomolecular engineering at Illinois. "In some cases, the scumlike residue clings to the nanoparticles and increases reaction rates and the amount of hydrogen peroxide formed instead of hampering the reaction. This observation made us wonder how it could be helping."

The team found that the residue, or surface redox mediator, holds oxygen-containing species, including a key component hydroxymethyl. It accumulates on the palladium nanoparticles' surface and opens new chemical reaction pathways, the study reports.

"Once formed, the residue becomes part of the catalytic cycle and is likely responsible for some of the different efficiencies among solvents reported over the past 40 years of work on this reaction," Flaherty said. "Our work provides strong evidence that these surface redox mediators form in alcohol solvents and that they may explain many past mysteries for this chemistry."

By working with multiple types of experiments and computational simulations, the team learned that these redox mediators effectively transfer both protons and electrons to reactants, whereas reactions in pure water transfer protons easily, but not electrons. These mediators also alter the nanoparticles' surface in a way that lowers the energy barrier to be overcome for proton and electron transfer, the study reports.

"We show that the alcohol solvents as well as organic additives can react to form metal-bound surface mediators that act much in the same way that the enzymatic cofactors in our bodies do in catalyzing oxidation and reduction reactions," Neurock said.

Additionally, this work may have implications for reducing the amounts of solvent used and waste generated in the chemical industry.

"Our research suggests that for some situations, chemical producers could form the surface redox mediators by adding small amounts of an additive to pure water instead of pumping thousands of gallons of organic solvents through these reactors," Flaherty said.