Precious metal-free silicone curing

Sustainable processes could replace precious metals in silicone crosslinking

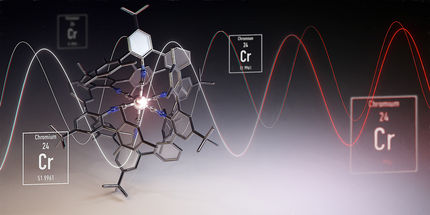

silicones are tried and tested in the private and professional domains. In many applications, however, expensive precious metals are required as catalysts to transform the liquid intermediate products to durable elastic polymers. A research team from the Technical University of Munich (TUM) and the Munich-based WACKER Group has now developed a curing process that works without precious metals.

Matthias Nobis with a newly developed silicone formulation. Silirane units replace the expensive precious metal catalysts that were previously used to crosslink silicones.

© Andreas Heddergott / TUM

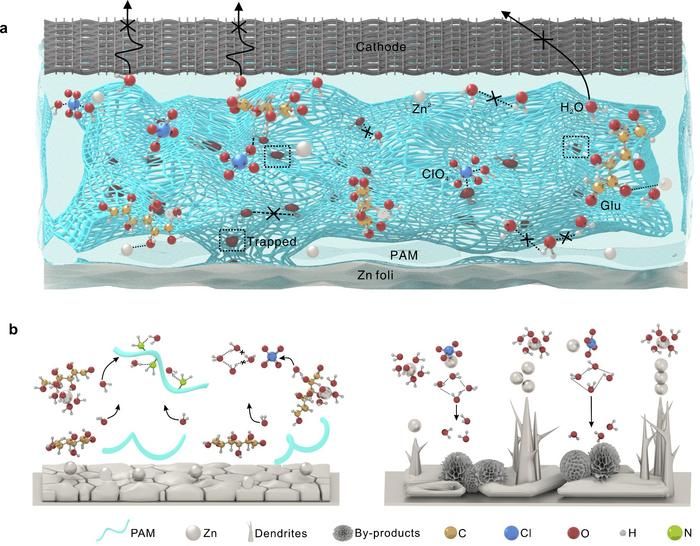

Silicones are synthetic polymers consisting of an inorganic silicon-oxygen backbone modified with organic side groups Before use, silicone must be converted to a rubber-elastic state through chemical crosslinking. One of the more important methods used in the industry is addition-curing, since this crosslinking process does not release any volatile byproducts and results in particularly high-quality silicone elastomers.

The process does have one disadvantage, however: the catalysts required for crosslinking contain precious metals such as platinum, which make the manufacturing process relatively expensive. These metals also remain in the silicone permanently.

Rings under strain replace precious metals

A research team headed by Professor Bernhard Rieger, who holds the WACKER Chair of Macromolecular Chemistry, and Dr. Richard Weidner, responsible for the organosilicon research at the Consortium for the Electrochemical Industry, the central research facility of the WACKER Group, has now found a promising approach to resolving this issue.

For the first time ever, the team successfully cured silicone rubber without using precious-metal catalysts. Rather than working with standard crosslinkers, the scientists used silicone building blocks with silirane units.

Siliranes are three-membered rings with a high degree of ring strain, which makes them reactive. The rings comprise one silicon atom and two carbon atoms, and can either react directly, upon ring-opening, with suitable functional groups – without releasing any byproducts – or generate what are known as silylenes through thermal or photochemical activation.

These highly reactive compounds can, in turn, react with any functional groups or synthetic building blocks typically used in the production of silicone rubber. Depending on the type of activation process and the choice of starting compounds, the method opens up a variety of pathways for curing silicones with silirane-containing crosslinkers.

High purity

Using selected silicone formulations the researchers at the WACKER Institute were able to demonstrate in the lab that the method can be used for crosslinking silicone rubber in this manner. The final properties are determined exclusively by the selection of starting products and their mixing ratio.

The silicone elastomers produced in this way are characterized by their exceptional purity. They contain neither volatile substances nor traces of precious metals. “That’s especially true for elastomers, which are crosslinked via a ring-opening reaction. Silicones like these are particularly suitable for medical applications or as encapsulants for the electronics industry,” says Bernhard Rieger.

Sustainable process

What makes this a trailblazing paper is that, for the first time, it shows, in principle, a way of making such highly reactive silicon compounds useful for industrial application. The researchers have to overcome a few more hurdles, however, to demonstrate practical viability in industrial use.

“But we can already clearly see the advantages of the method”, Rieger notes. “Given the global growth in demand for precious metals, which are only available in limited quantities, alternative concepts like the use of siliranes to crosslink silicone without precious metals could play an important role in protecting important resources.”

Original publication

Fabian A. D. Herz, Matthias Nobis, Daniel Wendel, Philipp Pahl, Philipp J. Altmann, Jan Tillmann, Richard Weidner, Shigeyoshi Inoue and Bernhard Rieger; "Application of multifunctional silylenes and siliranes as universal crosslinkers for metal-free curing of silicones"; Green Chem.; 2020, 22, 4489-4497

Original publication

Fabian A. D. Herz, Matthias Nobis, Daniel Wendel, Philipp Pahl, Philipp J. Altmann, Jan Tillmann, Richard Weidner, Shigeyoshi Inoue and Bernhard Rieger; "Application of multifunctional silylenes and siliranes as universal crosslinkers for metal-free curing of silicones"; Green Chem.; 2020, 22, 4489-4497

Topics

Organizations

Other news from the department science

These products might interest you

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

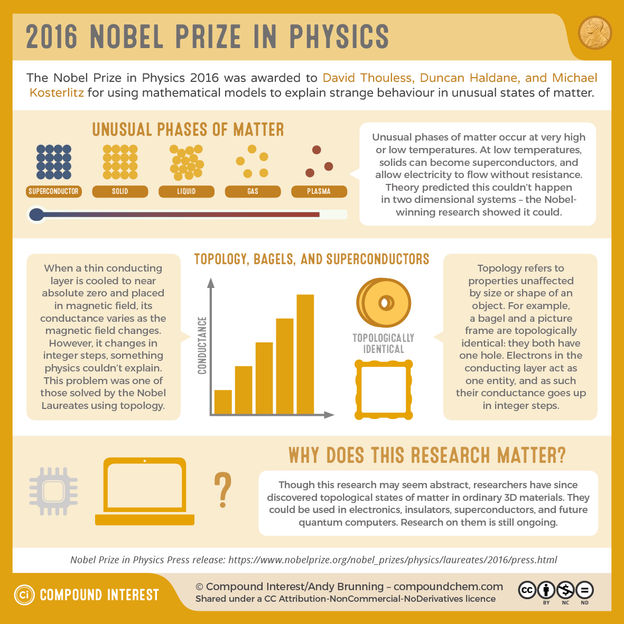

Nobel Prize in Physics 2016

LAUDA declared World Market Leader

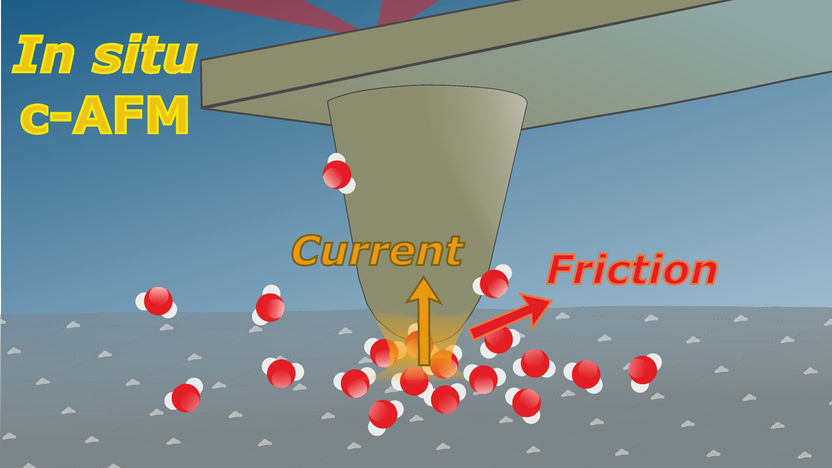

Electrocatalysis under the atomic force microscope - More insights with AFM

Edinburgh Instruments Ltd. - Livingston, United Kingdom

W. Dimer GmbH - Laufenburg, Germany

In chemical reactions, water adds speed without heat

More Electricity from the Sun - Surface modification for more effective textured perovskite/silicon tandem solar cells

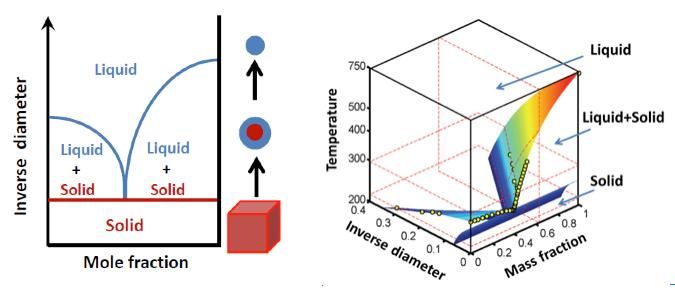

Solid or liquid - the particle size matters - Max Planck researchers elucidate how the phase state of aerosol nanoparticles depends on their size

Climate Change makes Arctic Ozone Loss Worse - The expected recovery of the ozone layer may fail to happen anytime soon, if global warming is not slowed down

Applied Biosystems/MDS Sciex is the Top Supplier in the Mass Spectrometer Market

Fighting microplastics for a cleaner future - Dr. Manish Shetty is working to break down microplastics to create usable fuel