Novel glass materials made from organic and inorganic components

Research team from Jena and Cambridge develops glass materials with novel combinations of properties

Linkages between organic and inorganic materials are a common phenomenon in nature, e.g., in the construction of bones and skeletal structures. They often enable combinations of properties that could not be achieved with just one type of material. In technological material development, however, these so-called hybrid materials still represent a major challenge today.

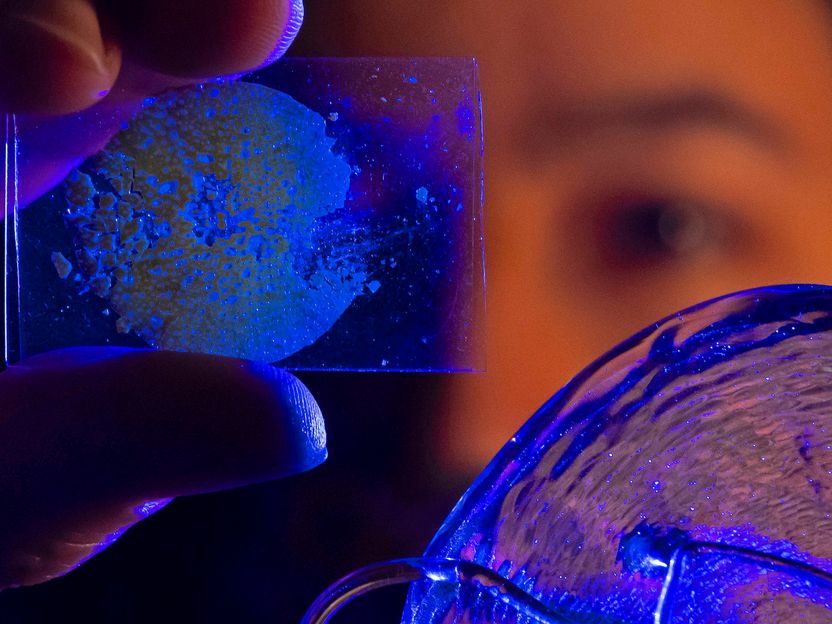

Dr. Courtney Calahoo presents organic (l.) and inorganic glass (r.).

Jens Meyer/Uni Jena

A new class of hybrid glass materials

Researchers from the Universities of Jena (Germany) and Cambridge (GB) have now succeeded in creating a new class of hybrid glass materials that combine organic and inorganic components. To do this, the scientists use special material combinations in which chemical bonds between organometallic and inorganic glasses can be generated. They included materials composed of organometallic networks – so-called metal-organic frameworks (MOFs) – which have recently been experiencing rapidly increasing research interest. This is primarily because their framework structures can be created in a targeted manner, from the length scale of individual molecules up to a few nanometers. This achieves a control of porosity which can be adapted to a large number of applications, both in terms of the size of the pores and their permeability, and in terms of the chemical properties prevailing on the pore surfaces. For example, separating membranes or storage devices for gases and liquids, supports for catalysts or new types of components for electrical energy storage devices can be designed.

“The chemical design of MOF materials follows a modular principle, according to which inorganic nodes are connected to one another via organic molecules to form a three-dimensional network. This results in an almost infinite variety of possible structures. A few of these structures can be converted into a glassy state by heat treatment. While crystalline MOF materials are typically synthesized in powder form, the liquid and glass states open up a wide range of processing options and potential shapes", explains Louis Longley from the University of Cambridge, UK.

Best of both worlds combined

“The combination of such MOF-derived glasses with classic inorganic glass materials could make it possible to combine the best of both worlds,” says Courtney Calahoo, a senior scientist at the Chair of Glass Chemistry at Friedrich Schiller University Jena, Germany. For example, composite glasses of this kind could lead to significantly improved mechanical properties by combining the impact and fracture toughness of plastics with the high hardness and rigidity of inorganic glasses. The decisive factor in ensuring that the materials involved are not simply mixed with one another is the creation of a contact area within which chemical bonds can form between the organometallic network and conventional glass. "Only in this way can really new properties be obtained, for example in electrical conductivity or mechanical resistance," explains Lothar Wondraczek, Professor of Glass Chemistry in Jena.

Original publication

Original publication

L. Longley, C. Calahoo, R. Limbach, Y. Xia, J. M. Tuffnell, A. F. Sapnik, M. F. Thorne, D. S. Keeble, D. A. Keen, L. Wondraczek, T. D. Bennett; "Metal-organic framework and inorganic glass composites"; Nature Communications 11 (2020)

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.