Programmable insulation materials

Innovative insulating materials made of shape memory polymers are developed and tested by the Fraunhofer Institutes for Applied Polymer Research IAP, for Chemical Technology ICT and for Building Physics IBP within the Fraunhofer Cluster of Excellence Programmable Materials CPM. The high-tech foams are to be used as functional materials, for example in the field of construction.

The synthesized shape memory polymers are processed on special reactive foaming equipment.

Fraunhofer IAP

The air conditioning of enclosed work, recreational and living spaces is of great social importance in industrialized countries. On average, people spend more than 80 percent of their time in these areas. If the room is poorly isolated, it can become very warm or very cold, depending on the season or even over the day.

Today, insulation materials represent an important technological solution to this problem. They make thermal insulation efficient and keep the cooling load or heating energy requirement and thus also the costs low. Since less climate-damaging carbon dioxide is emitted, they also protect the environment. Insulation makes both ecological and economic sense, because insulating materials save significantly more energy than is used in their manufacture. An additional improvement in the energy balance is possible through the use of bio-based raw materials, but also through insulating materials with programmable property profiles.

Programmable materials react autonomously

Programmable materials are shape- and function-dynamic materials, material composites or surfaces whose internal structure is such that the material properties and behavior can change reversibly following a program. This is achieved by permanently programming a material's response to a signal such as a change in temperature into the material structure. The response behavior can then be externally triggered so that programmable materials automatically adapt to changing conditions in a predetermined way.

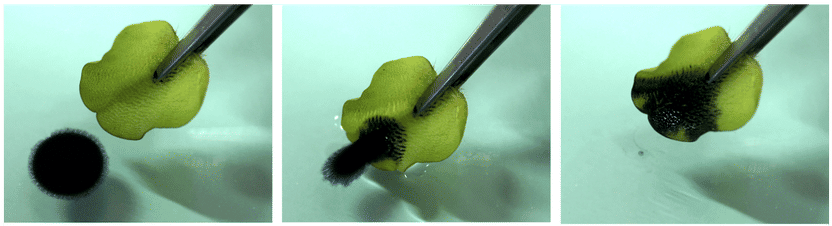

Foams made of shape memory polymer, e.g. polyester urethane urea, can also exhibit such actuator functionality. The dimensions of flow channels adjacent to or within the foams can be changed due to the switching capability. Accordingly, warm or cold air flows through the foam or the flow channels in a correspondingly good or bad way. At which temperature and in which direction the reversible shape change occurs can be determined in advance by the system design and by a thermomechanical treatment.

Foams made of shape memory polymer change their shape depending on the temperature

Researchers at the three Fraunhofer Institutes IAP, ICT and IBP are developing insulating materials with programmable material behavior based on such shape memory polymer foams. "We are developing autonomous insulation systems with switchable air permeability. Depending on the temperature, the insulating material changes its shape, e.g. the diameter of the flow channels and thus, also the heat transfer. At low temperatures, for example, the flow channels are closed and have an insulating effect. When heated, the channels open up and air can flow better through them. This is particularly interesting for applications in which outside temperatures change significantly. In our project, we have developed demonstrators for actuator elements for rear ventilation of the outer facade of a single-family house. This is a thermally switchable gap between the outer layer and the supporting structure of the building," explains Dr. Thorsten Pretsch, who heads the shape memory polymers working group at the Fraunhofer IAP.

Insulating materials for industrial applications

At Fraunhofer IAP, the programmable high-tech foams are synthesized and the technologies for programming the property profiles are developed. The temperatures at which the shape changes later occur, are already defined in the synthesis. For the optimal formulation of the foams, on the one hand the monomers are selected and the reaction conditions are adjusted, and on the other hand suitable additives or fillers are added, for example to influence the foam structure. The use of bio-based raw materials is also considered.

In order to be able to produce large quantities of insulating material for industrial applications, the Fraunhofer ICT is developing processes for scaling up polymer synthesis. In addition, the samples are subjected to non-destructive testing using micro computed tomography.

At the Fraunhofer IBP the heat transfer is evaluated in application-oriented tests. The mechanical properties are characterized and simulations for concrete applications are performed. "Our simulations of a ventilated facade of an apartment building in Madrid show that with the switchable insulation materials the operative room temperature could be reduced by 2.5 °C in the summer months or up to 46 percent of the energy for cooling could be saved", explains Prof. Dr. Martin Krus from Fraunhofer IBP.

The project to develop programmable insulating materials was launched on January 1, 2018, when the Fraunhofer Cluster of Excellence Programmable Materials was born, and has been running ever since. The researchers are also looking for new applications for the unique functionalities of shape memory polymer foams.