Catalyst Material from the Laser Lab

Industrial Relevance Proven

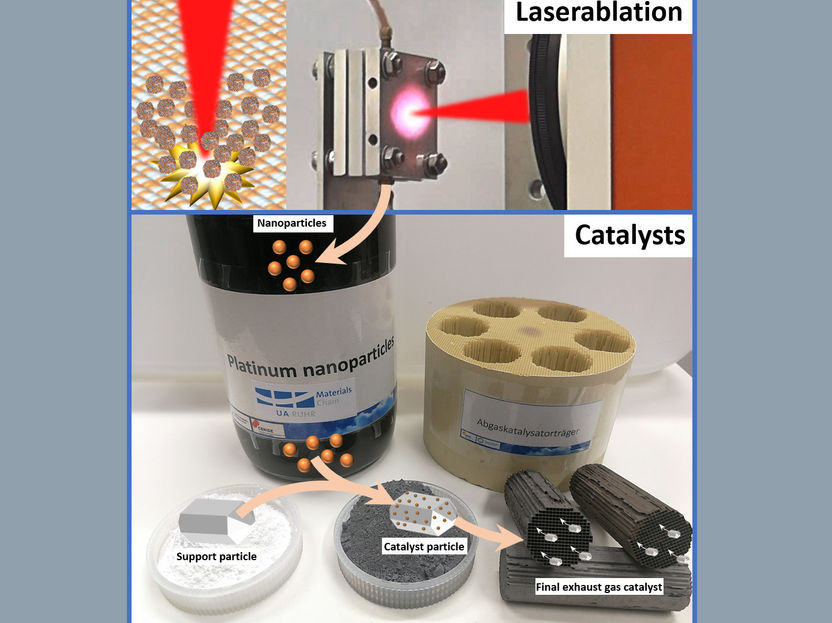

In catalysts, more surface area usually equals more activity. And hardly anything offers more surface than structures made of nanoparticles. Scientists from the Center for Nanointegration (CENIDE) at the UDE have shown that it makes sense in economic terms to produce catalytically highly active particles by laser. Not only are they extremely pure, but even at low temperatures they are more efficient than their conventionally produced counterparts. This has been demonstrated in tests conducted by an industrial partner.

From particle production to the final catalyst (schematic diagram).

© UDE/CENIDE

Exhaust gases from the diesel engine usually pass a catalytic converter consisting of platinum and palladium particles on an alumina carrier. The particles are smaller than 10 nanometers in diameter and have so far mainly been produced in a wet-chemical process, i.e. in a multi-step process that has to be optimized for each composition. Tests with new materials are therefore time-consuming and expensive.

Laser ablation, on the other hand, makes it possible to produce highly pure nanoparticles from a solid in one step. In this process, a laser vaporizes material from the surface of a platelet with ultra-short pulses. The platelet is made of the selected raw material and lies in a liquid. The fragments then assemble into nanoparticles. That's it.

The former disadvantage of the method: Until now, the output of the desired particle size was limited. But Dr. Sven Reichenberger from Technical Chemistry I and his team found a solution: "We placed the focus point of the laser slightly above the platinum-palladium plate in the solution." In this way, more than one gram per hour in the desired size can be produced selectively. The scientists who work at the NanoEnergieTechnikZentrum (NETZ) have thus exceeded the decisive limit where the laser method is more economical than thewet chemical method due to the low running costs. The trade magazine "Nanomaterials" covers this in its current issue.

Better Performance Even at Lower Temperatures

Umicore as industrial partner has tested the resulting particles under realistic conditions: Even at low temperatures the catalyst shows a much higher activity than the classic product. Moreover, it converts carbon monoxide equally well and nitrogen oxides even better into ecologically safe products.

"This was our milestone to prove the industrial relevance of the method," says Reichenberger. "Now we will test further materials."

Original publication

S. Dittrich, S. Kohsakowski, B. Wittek, C. Hengst, B. Gökce, S. Barcikowski, S. Reichenberger; „Increasing the Size-Selectivity in Laser-Based g/h Liquid Flow Synthesis of Pt and PtPd Nanoparticles for CO and NO Oxidation in Industrial Automotive Exhaust Gas Treatment Benchmarking“; Nanomaterials; 2020, 10(8), 1582

Most read news

Original publication

S. Dittrich, S. Kohsakowski, B. Wittek, C. Hengst, B. Gökce, S. Barcikowski, S. Reichenberger; „Increasing the Size-Selectivity in Laser-Based g/h Liquid Flow Synthesis of Pt and PtPd Nanoparticles for CO and NO Oxidation in Industrial Automotive Exhaust Gas Treatment Benchmarking“; Nanomaterials; 2020, 10(8), 1582

Organizations

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Stanford_V

Category:Human_mtDNA_haplogroups

Antiandrogen

Pseudoproline

Constantin_Carathéodory

Ecgonidine

Philosopher's_stone

Nanotechnology_in_fiction