Cascades with carbon dioxide

Novel catalytic process for converting CO2 into valuable chemical intermediates in the form of cyclic carbonates

carbon dioxide (CO2) is not just an undesirable greenhouse gas, it is also an interesting source of raw materials that are valuable and can be recycled sustainably. In the journal Angewandte Chemie, Spanish researchers have now introduced a novel catalytic process for converting CO2 into valuable chemical intermediates in the form of cyclic carbonates.

© Wiley-VCH

Getting CO2 to react is unfortunately not easy. Currently, most research is focused on the conversion of CO2) into methanol, which can be used as an alternative fuel as well as a feedstock for the chemical industry. Innovative catalytic processes could allow CO2 to be converted into valuable chemical compounds without taking a detour through methanol, perhaps for the production of biodegradable plastics or pharmaceutical intermediates.

One highly promising approach is the conversion of CO2 into organic carbonates, which are compounds that contain a building block derived from carbonic acid, comprising carbon atom attached to three oxygen atoms. Researchers working with Arjan W. Kleij at the Barcelona Institute of Science and Technology (Barcelona), the Institute of Chemical Research of Catalonia (Tarragona), and the Catalan Institute of Research and Advanced Studies (Barcelona), have developed a conceptually new process to produce carbonates in the form of six-membered rings, starting from CO2 and basic, easily accessible building blocks. These cyclic carbonates have great potential for the creation of new CO2-based polycarbonates.

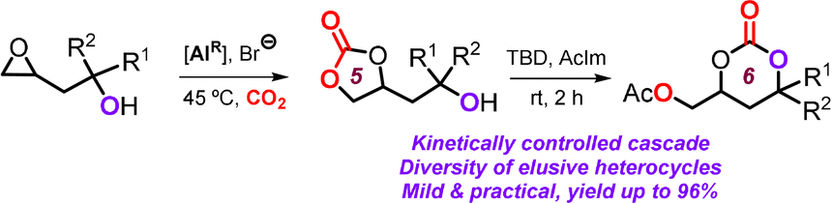

The starting materials are compounds with a carbon-carbon double bond and an alcohol group (-OH) on a neighboring carbon atom (homoallylic alcohols). In the first step of the reaction, the double bond is converted into an epoxide, a three-membered ring with one oxygen and two carbon atoms. The epoxide is able to react with CO2 in the presence of a specific catalyst. The product is a cyclic carbonate in the form of a five-membered ring with three carbon and two oxygen atoms. The carbon atom at the "tip" of the five-membered ring is attached to an additional oxygen atom. In the next step, an organic catalyst (N-heterocyclic base) activates the OH group and causes the five-membered ring to rearrange into a six-membered ring. The oxygen atom from the OH group is integrated into the new ring, while one of the oxygen atoms from the original five-membered ring forms a new OH group. However, the reverse reaction also takes place because the original five-membered ring is significantly more energetically favorable, and only a vanishingly small amount of the six-membered ring is present at equilibrium. The trick is to trap the six-membered ring. The new OH group binds to a reagent (acylation) because its different position makes it considerably more reactive than the original OH group.

This newly developed process gives access to a broad palette of novel, six-membered carbonate rings in excellent yields, with high selectivity and under mild reaction conditions. This widens the repertoire of CO2-based heterocycles and polymers, which are difficult to produce by conventional methods.

Original publication

Original publication

Chang Qiao et al.; "Organocatalytic Trapping of Elusive Carbon Dioxide Based Heterocycles by a Kinetically Controlled Cascade Process"; Angewandte Chemie International Edition; 2020

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.