Two for the price of one

Kyoto University simultaneously synthesizes dicarboxylic acids and hydrogen from diols

Every year, the chemical industry makes trillions of dollars synthesizing the countless chemical compounds we use every day.

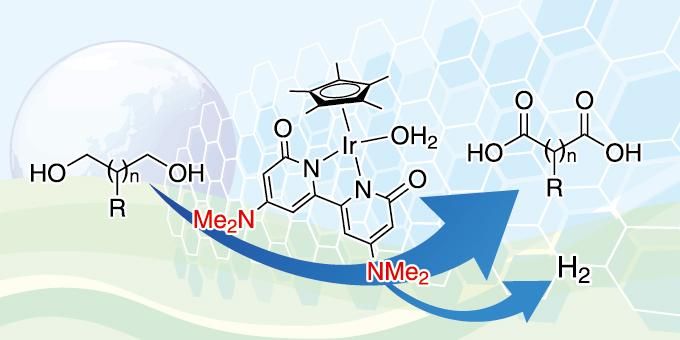

Using an iridium catalyst bound to a bipyridonate ligand, researchers were able to synthesize dicarboxylic acids from aqueous diols, with the added benefit of generating hydrogen as a byproduct

Kyoto University

From pharmaceuticals for keeping you healthy to polyester woven into your shirt, industrial processes turn simple chemicals into complex, valuable compounds. Researchers in turn work constantly to develop new substances as well as safer and more efficient methods of production.

In a paper published in ChemSusChem, researchers from Kyoto University's Graduate School of Human and Environmental Studies describe how they have significantly improved the process that leads to polymers and plasticizers. And as an added bonus, their method generates hydrogen as a byproduct.

"We use renewable chemical compounds collectively known as diols to dramatically change the synthesis of dicarboxylic acids," explains corresponding author Ken-ichi Fujita, "These are needed to produce polymers, plasticizers, and lubricants."

Existing production methods, based on the oxidation of hydrocarbons using toxic oxidants, generate harmful waste products. Knowledge of this motivated the team to work on a new method of synthesis, changing the initial compound along with the catalyst.

"We began by looking at liquid solutions of diols, which are more renewable than starting materials previously used," continues Fujita.

"Then we needed to find a catalyst, and we settled on using iridium bound to a bipyridonate ligand."

The team were pleased to find that combining the diols with the new catalyst generated dicarboxylic acids with greater efficiency and significantly more yield, as well as four equivalents of hydrogen for every unit of diols.

Developing more efficient and safer methods of compound production is vital for industrial organic chemistry, and for the global environment.

"It is a pleasant surprise to see how efficient our new process is," concludes Fujita. "We hope to continue to improve safety and efficiency as we discover alternative chemical processes that are valuable to all humanity."

Original publication

These products might interest you

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.