Special coating protects steel from hydrogen ‘attack’

Almost no evidence of brittleness

Regeneratively produced hydrogen is an ideal energy carrier, which will be used in future applications as fuel cells and cars and will supplement natural gas as an energy source. But atomic hydrogen often induces brittle behavior in metals at high temperatures. Lukas Gröner of the Fraunhofer IWM, MikroTribologie Centrum µTC, has now developed a robust coating that effectively protects steel from the penetration of hydrogen. The barrier effect of this so-called MAX-phase layer is 3500 times greater than that of untreated steel.

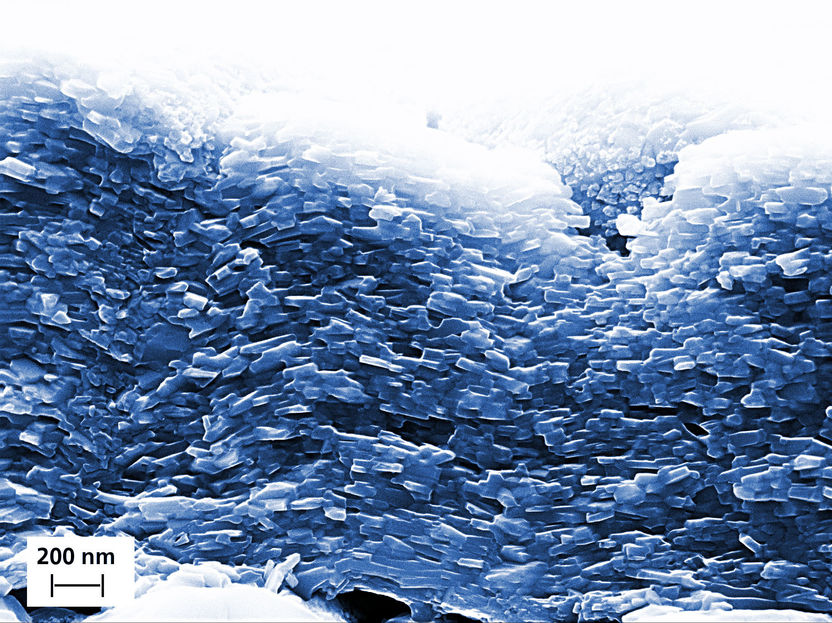

REM image of the fracture edge of a Ti2AlN coating with platelet-like shaped grains.

© Fraunhofer Institute for Mechanics of Materials IWM

The wind blows when it wants to. This is a real problem for the production of wind energy, because wind turbines do not always generate electricity when it is needed. In addition, there can be more electricity available in the power grid on windy days than is actually needed. That's why it makes sense to use the excess supply of wind and also solar power in a different way - for example to produce hydrogen. Hydrogen is an environmentally friendly energy carrier that can be stored very well. When burned, the only waste product is water. It can be mixed with natural gas and used in gas-fired power plants to generate energy. It can be used as fuel in cars or to generate electricity and heat in fuel cells. All of this makes hydrogen a beacon of hope for the energy revolution. But there are still a few hurdles to be overcome before hydrogen can be used on a large scale. One challenge is that atomic hydrogen makes metals brittle, which can lead to component failure. Atomic hydrogen accumulates in the parts of a component that are subject to particular stresses, such as at welding seams or in areas under tension. Hydrogen embrittlement then becomes a problem, especially in components that are exposed to high operating temperatures.

The hydrogen barrier combines the strengths of ceramics and metals

In his doctoral thesis at the Fraunhofer Institute for Mechanics of Materials IWM, MicroTribology Centrum µTC, and at the Institute for Microsystems Technology at the University of Freiburg im Breisgau, physicist Lukas Gröner developed and tested special coatings for steel components that virtually prevent the penetration of atomic hydrogen. These are so-called MAX-phase materials, which have been the subject of international research for over ten years. ‘MAX-phases have amazing properties because they combine characteristics of both ceramics and metals’ says Gröner, scientist in the Tribological and Functional Coatings Group at the Fraunhofer IWM.

MAX-phases, like ceramics, are insensitive to attack by oxygen and very heat-resistant. At the same time, they are electrically conductive like metals. Unlike pure ceramics, they are not brittle, so they do not break. Lukas Gröner has now succeeded in producing thin MAX-phase coatings that protect steel very well against corrosion and hydrogen embrittlement. In a vacuum chamber, he first deposited very precisely alternating layers of aluminum nitride, an aluminum-nitrogen compound, and titanium on a steel surface using physical vapor deposition (PVD). This sandwich structure, which is only about three micrometers thick, was then heated to form a very thin MAX-phase layer of titanium, aluminum and nitrogen (Ti2AlN). The challenge for Gröner was to control the deposition of titanium and aluminum nitride in such a way that parallel Ti2AlN platelets were formed during subsequent heating. He succeeded: ‘The platelets are close-packed like bricks in a wall’ is how Lukas Gröner describes the success.

In his doctoral thesis, Lukas Gröner also investigated how the MAX-phase coating behaves when it is intensively heated - as could be the case in future gas turbines or fuel cells. To simulate normal operating conditions, he heated the material to 700 degrees and left it in the furnace for up to 1000 hours. This created a thin layer of a special aluminum oxide on the top side of the coating – α -Al2O3. As was shown in the further course of the investigations, this thin aluminum oxide coating considerably increases the barrier effect of the protective layer against hydrogen.

New testing measures barrier effect against hydrogen

To test how well the MAX-phase layer prevents hydrogen from penetrating the metal, Lukas Gröner first developed a new test rig for thin metal sheets. In this test he compared uncoated steels with MAX-phase coated steels. This was the first time that it was possible at the Fraunhofer IWM to precisely quantify the penetration of hydrogen and to determine the so-called permeation reduction factor (PRF) as a measure for the barrier effect.

The results are impressive: steels with a MAX-phase layer that were not heated withheld hydrogen 50 times better (PRF 50) than untreated steels. But the results were particularly impressive for the coated steels that had been heated and formed an α-Al2O3 layer. These blocked the hydrogen from entering the metal roughly 3500 times better than with the untreated steel. ‘These are values that absolutely meet the requirements of the industry,’ emphasizes Gröner.

Lukas Gröner is currently testing how well the MAX-phase layers work when applied in collaboration with cooperation partners such as the Forschungszentrum Jülich - for example on high-temperature fuel cells (SOFC) that operate at temperatures of approximately 600 degrees Celsius. Says Gröner: ‘The MAX-phase coatings are ideal for these types of applications because they protect the metallic components from heat and at the same time can dissipate the electric current that is generated inside the fuel cell’. The coating is also suitable for gas turbines. In the future, more and more regeneratively produced hydrogen will be added to natural gas, which means that the gas will burn at a higher temperature. However, more hydrogen and higher temperatures increase the risk of hydrogen embrittlement, which is why a component coating with α-Al2O3 can be very advantageous. Gröner cannot say whether in the future, the new coating process will be offered by the industry as a service or if it will find its way into the market in another form. The individual PVD coating process steps also still need to be optimized. However, Lukas Gröner has at any rate proven that MAX-phase coatings can provide excellent protection against hydrogen.