Algae as living biocatalysts for a green industry

Discovery could lead to more environmental protection in the chemical industry

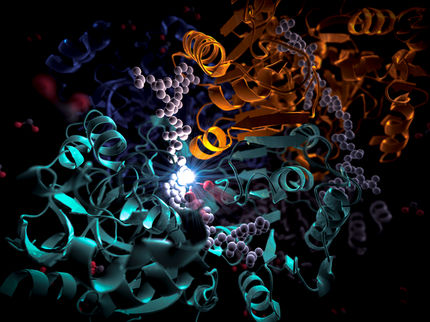

Many substances that we use every day only work in the right 3D structure. Natural enzymes could produce these in an environmentally friendly way – if they didn’t need a co-substrate that is expensive to produce to date. A research team at Ruhr-Universität Bochum (RUB) has discovered exactly the necessary enzymes in unicellular green algae. Better still: living algae can be used as biocatalysts for certain substances, and they bring the co-substrate along, producing it in an environmentally friendly manner through photosynthesis.

Algae hold great potential for environmentally friendly energy production.

© RUB, Marquard

It’s a question of 3D structure

Many chemical substances in cosmetics, food or medicines can assume slightly different three-dimensional structures, with only one of them generating the desired fragrance or medical effect. The chemical production of the right substances is often not environmentally friendly, as it requires high temperatures or special solvents. In nature, however, certain proteins do exist that produce the required product at mild temperatures and in water. In the process, they often generate exactly the 3D structure of the substance that is needed by the industry.

Old yellow enzymes require an expensive additive

These so-called old yellow enzymes, OYEs for short, owe their name to their naturally yellow colour. They occur in bacteria, fungi and plants, are in part well studied and offer considerable potential for a bio-based economy. However, they have one disadvantage: in order to carry out their reaction, they need the co-substrate NADPH (nicotinamide adenine dinucleotide phosphate). In living cells, this small molecule is generated through metabolic processes, whereas its chemical production is very expensive; as a result, the commercial use of OYEs is thwarted.

OYEs from unicellular green algae: two birds with one stone?

The research team from Bochum has discovered several OYEs in unicellular green algae. “For a broad application, industry needs OYEs that can also produce unusual molecules,” explains Professor Thomas Happe, Head of the Photobiotechnology research group at RUB. “Algae possess very complex metabolic pathways and are therefore ideal sources for novel biocatalysts.” The researchers analysed algal OYEs in the test tube and showed that they are able to convert many commercially viable substances. “The exciting thing is that living algae can also carry out the reactions needed in the industry,” points out PhD student Stefanie Böhmer, lead author of the study. “Since algae produce NADPH using photosynthesis, i.e. with sunlight, the co-substrate of the OYEs is supplied in an environmentally friendly and cost-effective way.”

Promising collaboration

The authors point out that the study demonstrates the importance of the collaboration between researchers from different disciplines, and that the industry can be a valuable partner who initiates basic research. Four researches from the Research Training Group “Micon – Microbial substrate conversion”, which is funded by the German Research Foundation, contributed their expertise to the study. The project was the brainchild of Solarbioproducts Ruhr, a spin-off established by Wirtschaftsförderungsgesellschaft Herne and Thomas Happe with the aim of developing concepts for environmentally friendly algae biotechnologies. “We have taken a big step towards a green industry,” concludes Happe. “This would not have been possible without collaboration.”

Original publication

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.