Printed perovskite LEDs

An innovative technique towards a new standard process of electronics manufacturing

A team of researchers from the Helmholtz-Zentrum Berlin (HZB) and Humboldt-Universität zu Berlin has succeeded for the first time in producing light-emitting diodes (LEDs) from a hybrid perovskite semiconductor material using inkjet printing.This opens the door to broad application of these materials in manufacturing many different kinds of electronic components.The scientists achieved the breakthrough with the help of a trick: "inoculating" (or seeding) the surface with specific crystals.

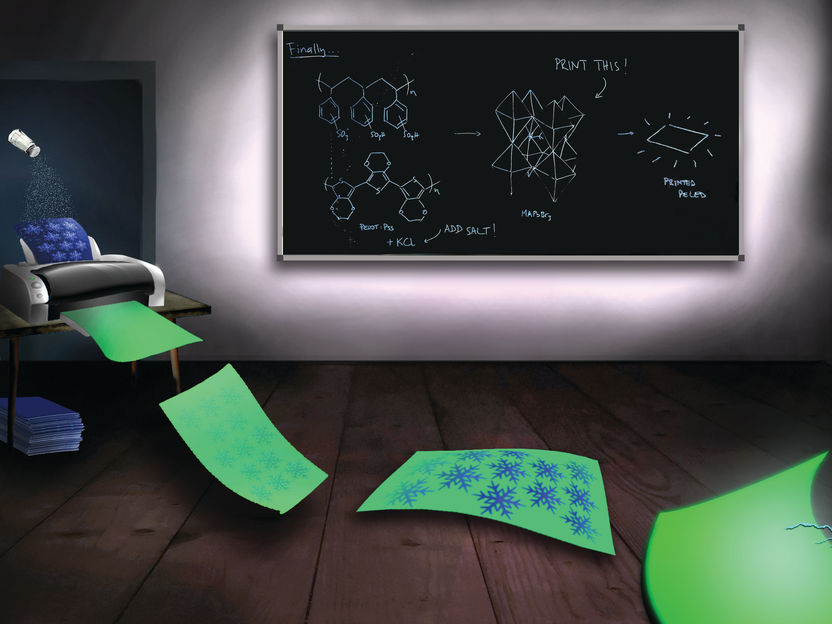

Graphic representation of the printing process for the perovskite LED.

© Claudia Rothkirch/HU Berlin

Microelectronics utilise various functional materials whose properties make them suitable for specific applications. For example, transistors and data storage devices are made of silicon, and most photovoltaic cells used for generating electricity from sunlight are also currently made of this semiconductor material. In contrast, compound semiconductors such as gallium nitride are used to generate light in optoelectronic elements such as light-emitting diodes (LEDs). The manufacturing processes also different for the various classes of materials.

Transcending the materials and methods maze

Hybrid perovskite materials promise simplification – by arranging the organic and inorganic components of semiconducting crystal in a specific structure. “They can be used to manufacture all kinds of microelectronic components by modifying their composition“, says Prof. Emil List-Kratochvil, head of a Joint Research Group at HZB and Humboldt-Universität.

What's more, processing perovskite crystals is comparatively simple. “They can be produced from a liquid solution, so you can build the desired component one layer at a time directly on the substrate“, the physicist explains.

First solar cells from an inkjet printer, now light-emitting diodes too

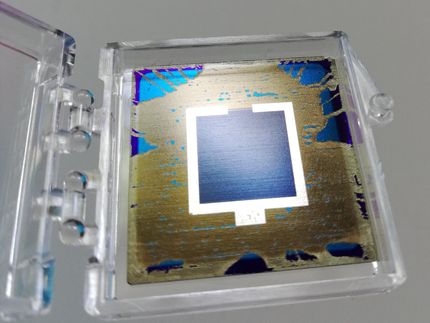

Scientists at HZB have already shown in recent years that solar cells can be printed from a solution of semiconductor compounds – and are worldwide leaders in this technology today. Now for the first time, the joint team of HZB and HU Berlin has succeeded in producing functional light-emitting diodes in this manner. The research group used a metal halide perovskite for this purpose. This is a material that promises particularly high efficiency in generating light – but on the other hand is difficult to process.

“Until now, it has not been possible to produce these kinds of semiconductor layers with sufficient quality from a liquid solution“, says List-Kratochvil. For example, LEDs could be printed just from organic semiconductors, but these provide only modest luminosity. “The challenge was how to cause the salt-like precursor that we printed onto the substrate to crystallise quickly and evenly by using some sort of an attractant or catalyst“, explains the scientist. The team chose a seed crystal for this purpose: a salt crystal that attaches itself to the substrate and triggers formation of a gridwork for the subsequent perovskite layers.

Significantly better optical and electronic characteristics

In this way, the researchers created printed LEDs that possess far higher luminosity and considerably better electrical properties than could be previously achieved using additive manufacturing processes. But for List-Kratochvil, this success is only an intermediate step on the road to future micro- and optoelectronics that he believes will be based exclusively on hybrid perovskite semiconductors. “The advantages offered by a single universally applicable class of materials and a single cost-effective and simple process for manufacturing any kind of component are striking“, says the scientist. He is therefore planning to eventually manufacture all important electronic components this way in the laboratories of HZB and HU Berlin.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.