Electric pulses precisely shape 3D-printed metal parts

Metal 3D printing with electrochemical machining combined

Professor Dirk Bähre and his research team at Saarland University have developed a non-contact method of transforming metal parts fabricated by a 3D printer into high-precision technical components for specialist applications. The novel method enables them to process parts made from strong, lightweight metals to produce precision-finished components with complex geometries and dimensional tolerances of a few thousandths of a millimetre. The team of manufacturing technologists combine metal 3D printing and electrochemical machining (ECM).

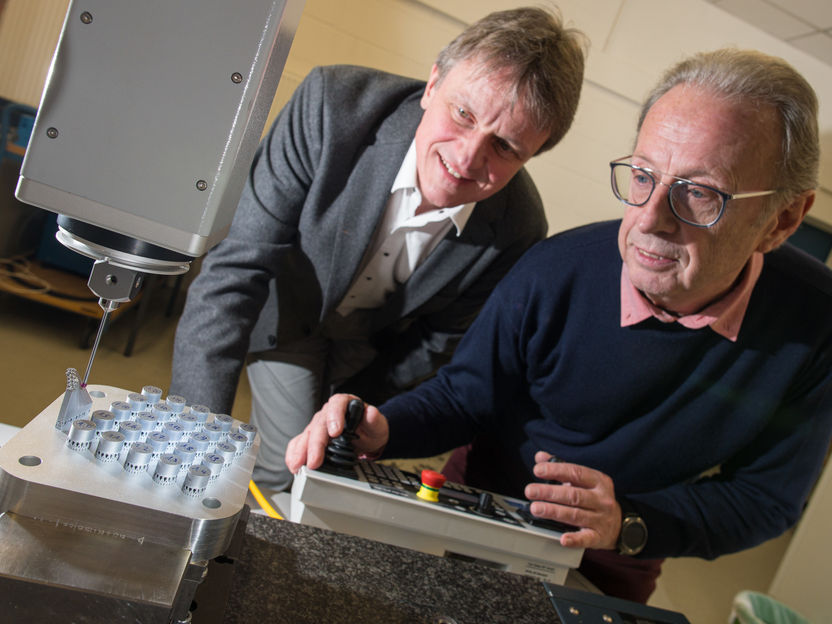

Professor Dirk Bähre (l., here with Stefan Wilhelm from his research group) and his team of researchers at Saarland University are specialists in the field of precision machining and finishing.

© Oliver Dietze

Complex technical systems like the engines that power cars, planes or rockets are made from a large number of highly specialized metal components. To ensure that all of these parts fit together perfectly and are able to withstand extreme mechanical stresses, each and every one of them has to be manufactured very precisely. ‘Tolerances can be down in the micrometre range,’ explains Professor Dirk Bähre from Saarland University. While metal 3D printing is now an established means of fabricating components with complex geometries, these additive processes, which build up the part layer by layer, are not sufficiently precise for components that have to meet extremely strict dimensional requirements. And in some cases, the geometry of the part may be too complex to be produced by conventional metal 3D printing.

Dirk Bähre and his research team have set themselves the goal of refining the workpieces from the 3D printer so that their dimensions are correct down to a few thousandths of a millimetre. ‘Our technology for post-processing additively manufactured metal parts offers a cost-effective means of producing high-precision functional surfaces for applications where extremely tight tolerances are crucial. It enables large numbers of parts to be post-processed efficiently and economically,’ says Bähre. He and his team of researchers at Saarland University are specialists in the field of precision machining and finishing. They have developed novel techniques in which they combine metal 3D printing with electrochemical machining.

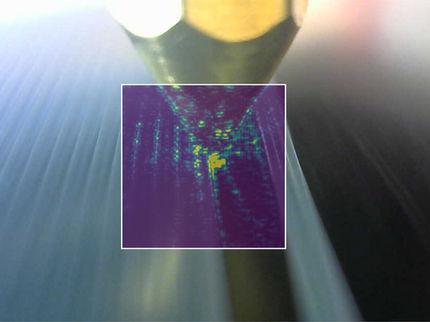

By removing material electrochemically, even the most complex geometries can be created in the hardest of metals. ‘Our non-destructive, non-contact manufacturing technology enables us to efficiently machine parts with intricate geometries even when made from high-strength materials,’ explains Bähre. The workpieces, which are bathed in a flowing electrolyte solution, can be electrochemically machined to the required geometry working to tolerances of a few thousandths of a millimetre – without any mechanical contact and without imparting any mechanical stresses to the workpiece. All the engineers need is a source of electrical power. A high electric current flows between a tool (the cathode) and the conductive workpiece (the anode), which has been produced in a 3D printing process. The workpiece is immersed in a conducting fluid (the electrolyte), which is simply an aqueous salt solution. The electrochemical machining process causes minute particles of metals to be removed from the surface of the workpiece. The metal atoms on the surface of the workpiece enter the solution as positively charged metal ions enabling the workpiece to very precisely attain the required geometric form. ‘By adjusting the duration of the current pulses and the vibration of the tool, we can remove surface material very uniformly leaving particularly smooth surfaces and achieving high dimensional precision,’ says Bähre.

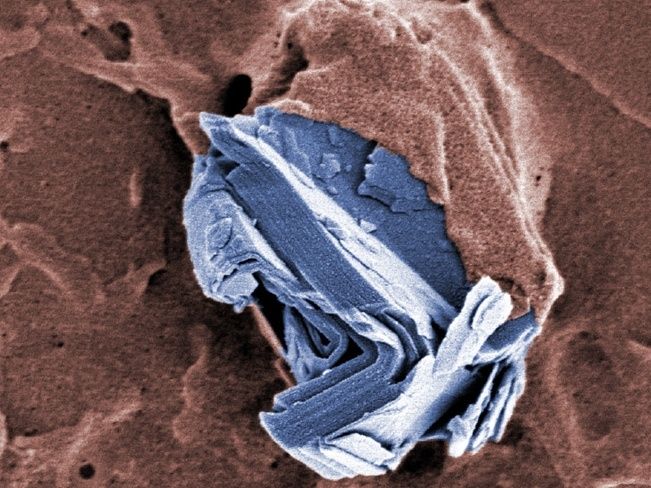

The researchers rigorously examine not only the metals used, such as aluminium, titanium or steel alloys, but also the individual process steps involved. ‘Optimizing post-processing requires a thorough understanding of both the material and the process. We need to know, for example, exactly what happened to the metal during the preceding 3D printing stage. That’s why we carefully study the microstructure of the metal produced in the 3D printing process. By meticulously examining both process technology and material behaviour, we can improve and optimize the electrochemical methods in order to obtain even smoother surfaces or more complex geometries at even higher levels of precision,’ explains Dirk Bähre.

The team carries out a large number of experiments in which they first fabricate the metal part using 3D printing technology and then determine how the subsequent electrochemical machining stage can be optimized to yield the required results. ‘We examine in detail how the different material and process parameters interact and then determine how the overall production process should be configured,’ explains Bähre. In some cases, for instance, the order in which the process steps are performed proves to be critical. The researchers conduct a systematic analysis of all the influencing parameters, performing highly-precise measurements and detailed analyses. As a result, the engineers have numerous means of fine-tuning the manufacturing process and tailoring the process parameters to meet application requirements.