Ceramic coatings for high-tech applications: New spraying method optimized

Powder Aerosol Deposition dense ceramic films can be applied to very different types of materials

For a long time, the production of ceramic coatings has only been possible by means of sintering techniques conducted at more than 1,000 degrees Celsius. However, a novel spraying method, Powder Aerosol Deposition (PAD), enables their production at normal room temperatures. It is therefore highly attractive for industrial applications. Engineering scientists from the University of Bayreuth under the direction of Prof. Dr.-Ing. Ralf Moos are working in the frontline of ongoing development of this technology. In the journal of "Advanced Materials", they present its advantages and show how the functional properties of ceramic films can be optimized with regard to high-tech applications.

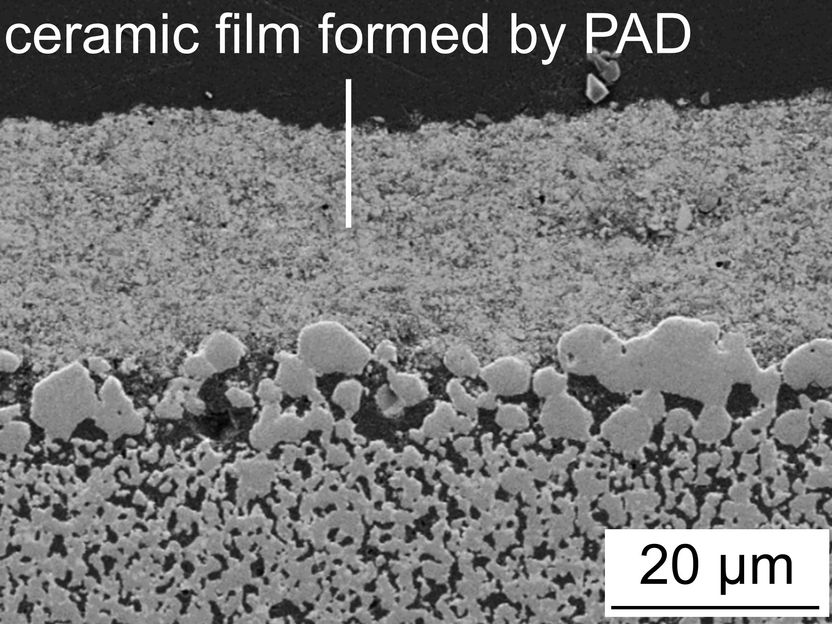

A ceramic film produced by powder aerosol deposition on a porous gas-permeable electrode, such as those required in fuel cells.

Jörg Exner

With PAD, dense ceramic films can be applied to very different types of materials, such as steel, glass, silicon, or even plastic. To achieve this, a dry ceramic powder is first converted into an aerosol, i.e. a mixture of gas and solid particles, with the aid of a carrier gas. The aerosol is then transported into a vacuum chamber, and accelerated to several 100 meters per second through a nozzle and directed onto the material to be coated. On impact, the tiny ceramic particles fracture. The resulting fragments, only a few nanometers in size, feature fresh, active surfaces. They form tightly adhering, dense coatings with a thickness of between 1 and 100 micrometers.

"Thanks to their dense microstructure, the coatings already exhibit excellent mechanical properties even directly after the deposition. They are extraordinarily hard and have good chemical resistance," explains Dr.-Ing. Jörg Exner, first author of the study, who was a driving force in the research work on PAD at the University. However, as it turned out, some functional properties of the coatings, especially the electrical conductivity, proved inadequate without carrying out further steps. In their new study, nevertheless, the Bayreuth engineering scientists are now able to report on effective methods of optimization.

Crystalline structures are of crucial importance in this context. The strong impact of the ceramic particles on the materials causes structural defects in the resulting fragments. This not only affects electrical conductivity, but also other functional properties. "By a thermal post-treatment, or so-called tempering, these defects can be almost completely eliminated. We have been able to show that the required temperatures are generally much lower than for conventional sintering. The avoidance of these extremely high temperatures is what makes PAD so attractive. It therefore remains true: This technology offers very high industrial potential, especially where high-quality ceramic coatings are required,” Exner concludes.

What type of ceramic materials are processed depends on the intended technological applications: Dielectric ceramics are suitable for capacitors, electrically conductive functional ceramics are preferred for sensors, and yttrium-stabilized zirconium oxide is used in high-temperature fuel cells. Even lithium-ion batteries can be produced in this way.

The scientific understanding of the ceramic film structures and of their functional properties, gained at the University of Bayreuth, will contribute significantly to the goal of integrating high-quality coated components into complex systems in a sustainable way. New technologies, for example, in the fields of energy storage and conversion, or for the purpose of environmental monitoring, therefore stand to benefit considerably from powder aerosol deposition applications.

Original publication

Original publication

Jörg Exner, Tobias Nazarenus, Dominik Hanft, Jaroslaw Kita, Ralf Moos; "What Happens during Thermal Post? Treatment of Powder Aerosol Deposited Functional Ceramic Films? Explanations Based on an Experiment? Enhanced Literature Survey"; Advanced Materials; 2020

Organizations

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.