Now things are getting big - innovative membrane reactor on its way to being an industrial scale

Consortium of 24 partners: Innovative plant combines several previously separate production steps

Evonik is continuing to strengthen its position as one of the leading companies in the field of C4 chemistry. MACBETH (Membranes And Catalysts Beyond Economic and Technological Hurdles), the largest EU-funded project coordinated by Evonik to date, was recently launched The aim is to develop a new process for catalytic synthesis with appropriate separation equipment in a single, highly efficient catalytic membrane reactor (CMR). MACBETH is the follow-up project to the ROMEO project (Reactor Optimization by Membrane Enhanced Operation), which was completed in September 2019.

Technikum of Performance Intermediates

Evonik

The newly founded project consortium consists of 24 partners from ten different countries. It brings together expertise related to catalysis to membranes, carriers, reactors, engineering, modelling as well as the perspective of the end user.

"It is crucial that we think beyond the boundaries of chemistry, share knowledge and exploit synergies. One individual company could never achieve this. Our consortium brings together the know-how that is essential for the desired breakthrough in catalytic synthesis," says Dr. Marc Oliver Kristen, Head of the Innovation Agency at Evonik and Project Manager MACBETH.

In individual sub-projects, the concept of the new reactor is now being applied to various chemical reactions and put into practice. This includes hydroformylation for specialty chemicals, hydrogen production for the transport/electricity generation sector, propane dehydrogenation (PDH) for large-volume chemicals and biocatalytic oil cleavage for biotechnologically manufactured products.

Evonik’s focus of the project is on the hydroformylation reaction. In this catalysis, which is traditionally carried out homogeneously, synthesis gas is used to convert olefins into aldehydes.

Sustainability is a key driver here: the planned reduction of greenhouse gas emissions in large-volume industrial processes will be up to 35% and the increase in resource and energy efficiency up to 70%.

Furthermore, the new reactor design not only guarantees considerably smaller and even safer production plants. It also helps to strengthen the leading role in the market, because in future, the investment costs (CAPEX) and operating costs (OPEX) of systems of this type can be reduced by up to 50% and 80% respectively.

"Our next milestone is clear: We want to implement and operate a demonstration plant under real, industrial conditions," says Prof. Dr. Robert Franke, Project Coordinator of the overall MACBETH project and Head of Hydroformylation Research at Evonik. "Therefore, we will now, in the first project phase of MACBETH, concentrate on the optimization of the components used and the final reactor system. For this purpose, we will utilise the promising developments and results from the previous project."

Other news from the department business & finance

Most read news

More news from our other portals

See the theme worlds for related content

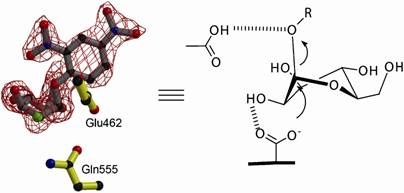

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.