Stora Enso invests in pilot plant for bio-based plastic packaging material

Stora Enso is investing EUR 9 million to build a pilot facility for enabling the production of bio-based plastics as barrier in transparent packaging. The pilot plant will convert plant-based sugars into the renewable building block required to make PEF, a bio-based plastic, mainly targeting the food and beverage industry. The pilot plant will be located at Stora Enso’s Langerbrugge Mill in Belgium.

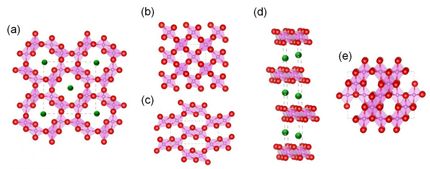

FDCA crystals

Stora Enso Oyj

The investment in bio-based chemistry further strengthens Stora Enso’s opportunities to replace fossil-based materials with renewable and recyclable materials. The pilot plant will focus on developing a cost-competitive process for manufacturing FDCA (furandicarboxylic acid) from sugars. FDCA is a key component of the bio-based barrier material PEF (polyethylene furanoate). In addition to its renewable nature, PEF’s attractive barrier, mechanical and thermal properties open up new packaging opportunities, such as small liquid containers for soft drinks, juices and other beverages.

“Bio-based materials are of rapidly growing interest in the packaging world as companies look for sustainable packaging materials with high performance,” says Markus Mannström, Executive Vice President of Stora Enso’s Biomaterials division. “With this pilot, we continue to build on our long-term R&D work while targeting new markets with innovative, renewable materials that replace fossil-based materials. We believe that innovation does not happen in isolation. We are, therefore, looking forward to expanding our cooperation within the field of bio-based chemicals,” Mannström says.

Stora Enso’s pilot aims to validate the chemical process and provide sample material to gain further insight into market need and product demand. The pilot facility will initially use industrially available fructose to produce high-value chemicals and materials for application testing. In the future, the intention is to run the process on sugars extracted from wood and other non-food biomasses.

The new pilot project will be run by Stora Enso’s Biomaterials division. The Langerbrugge paper mill provides space and infrastructure for hosting the facility. Also, the Ghent area in Belgium is home to a large number of chemical production sites. The design and engineering of the pilot facility have started, and construction will begin in the second half of 2020. The plant is estimated to be ready in the first quarter of 2021. Decisions about commercialisation will follow after evaluating the results of the pilot-scale production.

Topics

Organizations

Other news from the department business & finance

These products might interest you

ERAVISC X by eralytics

2 in 1: Viscosity & density with lab-precision

Viscosity and density measurement according to ASTM D445, D7042, D4052 and ISO 12185

Tensíío by KRÜSS

Break-through in tensiometry

One device, 15 methods for analyzing surface and interfacial tension and wettability

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.