Evonik and Dow develop industrial-scale direct synthesis of propylene glycol from propylene and hydrogen peroxide

Dow and Evonik have entered into an exclusive technology partnership. Together, they plan to bring a unique method for directly synthesizing propylene glycol (PG) from propylene and hydrogen peroxide to market maturity.

Aircraft de-icing fluids based on propylene glycol play an important role in providing safe, uninterrupted, and timely air travel during inclement conditions.

©Adobe Stock/chalabala

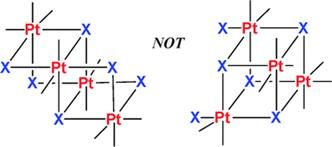

The basis for the method, named HYPROSYN™, has been created over the last few years by a team of over 100 Evonik employees. The key element is a novel catalytic system developed by Evonik researchers which allows for the direct synthesis of PG from propylene and hydrogen peroxide, in a process offering high yield and comparatively low energy consumption.

Some 1.9 million metric tons of propylene glycol were used worldwide in 2018. The molecule is used in the production of polyester resins and as a de-icing agent. It is also an important food additive and serves as a humectant and co-surfactant in many products in the home and personal care market.

“We are very pleased to be cooperating with Dow to bring the HYPROSYN™ process to market maturity. Dow is by far the largest producer of PG worldwide and a world leader in the field of material science. Dow’s technical and market experience will be invaluable in the scale up of our development” says Michael Träxler, the head of Evonik’s Active Oxygens business line.

A pilot plant is to be constructed at the Evonik site in Hanau by the end of 2020, with large-scale technical implementation to follow a few years later. “We believe that the new HYPROSYN™ direct synthesis technology will enable a more competitive route to produce PG with an improved environmental profile, providing us greater flexibility in serving our customers" says Andrew Jones, global business director for Propylene Oxide, Propylene Glycol,

Chlor-Alkali and Vinyl at Dow. Dow is the only truly global PG producer with five production facilities located on four continents.

In the traditional process propylene oxide (PO) is converted to PG using water. According to the company, the HYPROSYN™ technology offers several advantages over that process:

- It is expected to consume significantly less energy while providing a higher yield.

- The HYPROSYN™ process combines all reaction steps in a single reactor, eliminating the need for investment in additional PO capacity. Existing PG plants can be retrofitted with little effort.

- Only hydrogen peroxide and propylene are processed as feedstock, increasing flexibility and lowering total investment cost.

“In addition to potential license revenue, this partnership also demonstrates how we create new areas of application for hydrogen peroxide and positions us as a preferred provider," said Träxler. In recent years, the molecule has become established as an important oxidizing agent for chemical synthesis – not least as a result of the HPPO process for the production of propylene

oxide.

“We are pleased to work together with Evonik to bring this sustainable and innovative new technology to market. We believe it is an important development in support of growing demand

from our PG customers worldwide” says Jones.

Other news from the department business & finance

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.