LANXESS planning AI-assisted formulation development for Urethane Systems

LANXESS is broadening its use of artificial intelligence (AI) in product development. The specialty chemicals company has launched a project aimed at expanding its range of prepolymers. The goal is to offer customers tailor-made polyurethane systems with even shorter lead times, including for entirely new applications with different requirements. The Urethane Systems business unit is using the potential of AI and has brought materials AI company Citrine Informatics on board as a project partner.

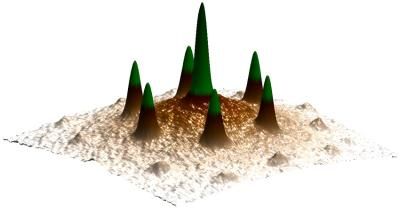

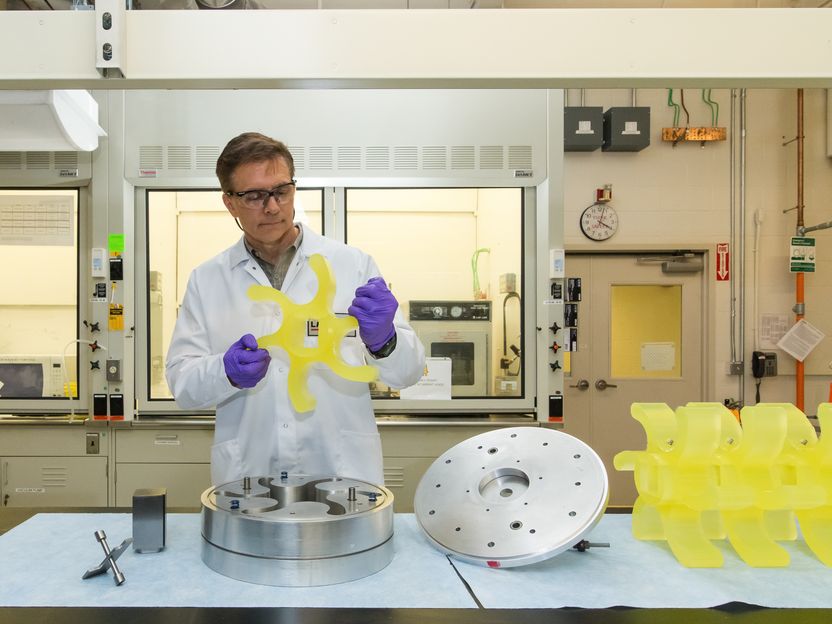

LANXESS develops numerous prepolymers for a wide range of polyurethane applications, such as star wheels for material separation and material transport. The use of artificial intelligence is expected to speed up the process of developing custom-made formulations for prepolymers. Tests are currently being conducted at the research and development laboratory in Naugatuck, U.S.

LANXESS AG

In an initial project phase, LANXESS enlarged its database of prepolymer-based formulations. LANXESS data specialists and process experts used the Citrine Platform for artificial intelligence to add further data points to the company's formulation database. This involved linking existing empirical measurement data with the knowledge of the process experts and a chemistry-aware algorithm to calculate additional measurement values. This meant that only a few real-life measurements were required to verify the figures determined with AI.

In a next step, data and process experts at LANXESS will check how reliably optimal formulations can be predicted with the aid of AI to meet customer-specific requirements for product characteristics. “If the next tests are successful, we will be able to fulfill customer requests even more quickly and effectively. Our existing knowledge of formulations shall be enhanced by AI-assisted formulation design – in other words, systems that are not yet part of our portfolio but for which artificial intelligence will enable us to know instantly whether we can manufacture them and how,” says Markus Eckert, head of the Urethane Systems business unit at LANXESS.

AI complements domain knowledge

So far, chemists have largely had to rely on their specialist expertise and years of experience when researching new formulations with defined product characteristics such as hardness, tensile strength and viscosity. AI is expected to become an important tool to help them broaden their knowledge and significantly reduce the amount of tests required.

LANXESS already has some experience in using AI. In a pilot project with Citrine Informatics, the specialty chemicals company is using AI to optimize glass fibers as a way of further enhancing the properties of LANXESS high-performance plastics. It is anticipated that AI will cut development times for the necessary formulations by more than half. Customers will receive even better, tailor-made products within shorter time frames.

For Jörg Hellwig, Head of the LANXESS Digitalization Initiative, the partnership between Citrine and the LANXESS Urethane Systems business unit demonstrates the growing role of digitalization in product development. “Most employees who are already using artificial intelligence cannot imagine ever going back to the old methods of working. The use of digital technologies is increasingly becoming standard procedure at LANXESS,” says Hellwig.

Organizations

Other news from the department business & finance

These products might interest you

New

New

Data Management Platform by LabV Intelligent Solutions

Turn data into better products

Maximum efficiency in the laboratory with LabV’s AI-powered data management platform

ALPHA II by Bruker

Chemical analysis made easy: compact FT-IR system

Increase the efficiency of your routine analyses with user-friendly technology

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.