Determining the activity of noble-metal-free catalyst particles

Noble-metal-free nanoparticles could serve as catalysts for the production of hydrogen from water. Because they are so small, their properties are difficult to determine.

Corina Andronescu, Tsvetan Tarnev and Harshitha Barike Ayappa are discussing an experiment using scanning electrochemical cell microscopy.

© RUB, Kramer

Chemists have developed a new method with which they can characterise individual noble-metal-free nanoparticle catalysts. The particles could be a cheap alternative to precious metal catalysts for obtaining hydrogen from water by means of electrolysis. “In order to develop effective nanoparticles, we need to understand how the structure and activity of individual particles or small particle groups are related to each other,” says Professor Wolfgang Schuhmann of the Center for Electrochemistry at Ruhr-Universität Bochum. He describes a new measurement method for this purpose together with the researchers Tsvetan Tarnev and Dr. Harshitha Barike Ayappa from Bochum and Professor Corina Andronescu from the University of Duisburg-Essen and other colleagues in the journal “Angewandte Chemie” of 1 October 2019.

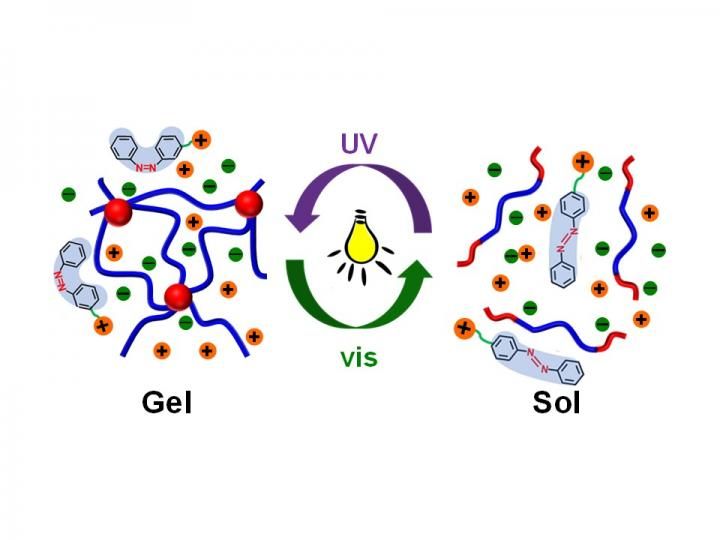

So far, there are few techniques available to measure the catalytic activity of individual or a few nanoparticles. “The currents that have to be measured are extremely small, and one has to find single or few nanoparticles in order to measure them reproducibly,” explains Schuhmann. The research team, which cooperates within the University Alliance Ruhr, showed that such analyses are also possible with high throughput – namely with scanning electrochemical cell microscopy.

Development of a new reference system

Until now, the method had not been used for this purpose because the nanoparticles had to be tested under demanding chemical conditions and thus large measurement inaccuracies occurred. This made a reliable interpretation of the results impossible. In their current work, the researchers developed a new reference system for scanning electrochemical cell microscopy. By cleverly using a stable internal standard, they eliminated the measurement inaccuracies and enabled long-lasting measurements under the given conditions with high throughput.

Analysis of self-made nanoparticles

The researchers produced carbon particles with nitrogen and cobalt inclusions on glassy carbon, the particles being present on the surface either individually or in groups of a few particles. In a single experiment, they were able to use scanning electrochemical cell microscopy to determine the electrochemical activity of all these individual particles or particle groups.

The particles catalysed the so-called oxygen evolution reaction. The electrolysis of water produces hydrogen and oxygen – the limiting step in this process is currently the partial reaction in which oxygen is evolved; more efficient catalysts for this partial reaction would facilitate the production of hydrogen.

Original publication

Tsvetan Tarnev, Harshitha Barike Aiyappa, Alexander Botz, Thomas Erichsen, Andrzej Ernst, Corina Andronescu, Wolfgang Schuhmann; "Scanning electrochemical cell microscopy investigation of single ZIF‐derived nanocomposite particles as electrocatalysts for oxygen evolution in alkaline media"; Angewandte Chemie International Edition; 2019

Original publication

Tsvetan Tarnev, Harshitha Barike Aiyappa, Alexander Botz, Thomas Erichsen, Andrzej Ernst, Corina Andronescu, Wolfgang Schuhmann; "Scanning electrochemical cell microscopy investigation of single ZIF‐derived nanocomposite particles as electrocatalysts for oxygen evolution in alkaline media"; Angewandte Chemie International Edition; 2019

Topics

Organizations

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.