Inspired by nature: Scientists have developed a nanopore-microchip

Medical professionals and environment analysts would like to have microchips that measure substances directly on site. Scientists at TU Darmstadt have developed and patented a system based on nanopores with broad potential.

Professor Wolfgang Ensinger and Ivana Duznovic examine their highly sensitive product: A chip with sensors made of synthetic nanopore.

Katrin Binner

Anyone wishing to use laboratory readings for diagnosing a disorder or its progress monitoring or wanting to test the contamination of waste water with pesticides or medicines must almost always send the samples to a laboratory and wait for the results. That takes time. A “lab-on-a-chip system” determines the readings directly at the doctor’s or the sampling site.

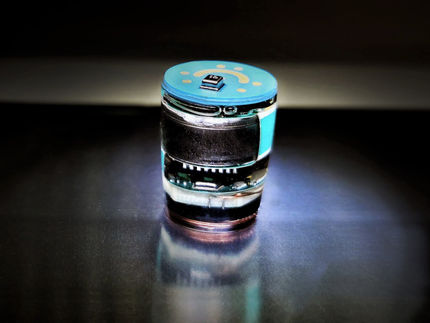

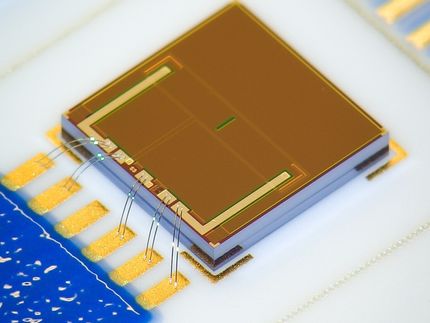

As big as a credit card and with the functionality of a laboratory, these systems work faster, less costly and more efficiently than a classic laboratory while still having to be just as precise, robust and reliable. The research groups led by Wolfgang Ensinger, professor for materials technology and Helmut Schlaak, professor for electrical engineering and information technology at TU Darmstadt, have developed as part of the LOEWE project iNAPO a prototype for a “lab-on-a-chip system” that measures substances with sensors made of synthetic nanopores. The chemist Ivana Duznovic and the electrical engineer Mario El Khoury are participating in the project.

The scientists were inspired by nature in their work. Integrated into the cell membranes, biological nanopores ensure that substances can be transported from the outside to the inside or vice versa. In so doing, they function as either sluices or selective transport systems that are specialised in certain substances. There has hitherto been no technical system that can compete with the sensitivity and specificity of biological nanopores. Their performance capability is unsurpassed. Biological nanopores are themselves, admittedly, unsuited to technical application as they are too fragile. Ensinger and Duznovic decided therefore to use synthetic nanopores, which they equipped with a chemical or biological sensor. To this end, the surfaces of the nanopores were correspondingly functionalised. “Our aim is to develop a new generation of sensors that closely aligned to their biological models offer high sensitivity and performance capability”, Ensinger says. “When we then integrate these bio-inspired sensors into a microfluid system with portable analysis electronics, it becomes a “lab-on-a-chip system”, Schlaak adds.

Admittedly, several steps are necessary for this. Firstly, the synthetic nanopores have to be produced. This occurs by way of bombarding polymer foils with heavy ions. This task is carried out by the GSI Helmholtz Centre for Heavy Ion Research in Darmstadt. After the foils have been bombarded, the nanopores are enlarged and brought into a conical shape.

They then have a narrow and a wide opening and look like a funnel. The nanopores are enlarged by treating the foil on one side with an alkaline solution. “Via the caustic process, free carboxy groups arise via which the nanopores can then be functionalised using coupling chemistry”, Ivana Duznovic explains. “We can basically attach anything we want to the carboxy groups. However, only such substances are suitable that are biologically or chemically relevant and with the help of which we can verify biomolecules relevant for diagnosis or environmental analysis purposes with high specificity and sensitivity. The sensor would otherwise make no sense”.

The nanopores were functionalised for among other things the verification of histamine. Histamine plays a key role in allergic reactions and could also be important in connection with Alzheimer’s dementia. The verification that Ensinger and Duznovic have created is based on a displacement reaction.

A substance coupled to a carboxy group binds a metal ion that can also bind to histamine. If the sample contains histamine, the metal ion moves to the histamine, which can be recognised by a drop in current through the nanopores. The rule here is: the stronger the current falls, the more histamine there is in the sample. As the substance coupled to the carboxy group can be recharged with the metal ion, the nanopores can be regenerated and used for further verification.

The next step is the development of the “lab-on-achip system”. “We already have a functioning microchip, but there are still some problems to be solved as the verification is supposed to function not only in watery solutions but also in a blood sample” Schlaak says. As the team would like to re-use the chip for cost reasons and as this is basically possible due to the regenerability of the nanopores, there should be no falsification of subsequent results from the initial usage. “We cannot have any memory effect”, El Khoury puts the problem in a nutshell. A “bottleneck” for commercialisation is also the search for a suitable candidate for corresponding verification, for medicine for example. “We need a marker that has already been correspondingly validated”, Ensinger says. “It must be certain that the verification is actually sensible and helpful, for the diagnosis, screening or progress monitoring of a disorder, for example”, the materials technologist continues. “We are currently on the lookout for interesting candidates and are already collaborating with Mainz University Hospital. However, we are open to other ideas.”

A “lab-on-a-chip system” based on bio-inspired nanopores can only be created in close cooperation with other disciplines. Ensinger and Schlaak are therefore full of praise for the interdisciplinary procedure of the LOEWE project iNAPO. Chemists, biologists, materials technologists, physicists and electrical engineers were involved in the development. “We are very well prepared for such projects at TU Darmsatdt”, Ensinger says. As the next step, the team would like to equip the surfaces of the nanoprobes for the verification of proteins to thus also identify complex biomarkers.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.