LANXESS inaugurates high-tech plastics plant in China

Specialty chemicals company LANXESS officially inaugurated its new plant in Changzhou, China, on September 25, 2019. The compounding facility produces Durethan- and Pocan-branded high-tech plastics, especially for the automotive sector and the electrical and electronics industry.

“This facility was built to address several strategically vital markets,” said Hubert Fink, Member of the LANXESS Board of Management, in his speech at the opening ceremony. “In the automotive industry, lightweight materials become ever more important in new mobility. At the same time, the electrical & electronics sector sees an increasing need for best-in-class flame retardant, easy flow and easily processable grades.”

“With the new plant, we are responding to the trend towards the increased use of lightweight materials. We are committed to this long-term development,” said Michael Zobel, Head of the High Performance Materials business unit.

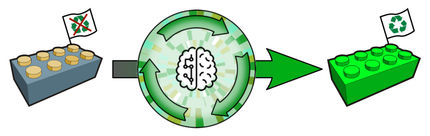

Entire production system designed to be intelligent

Intelligent production is a substantial highlight of the new plant. From batching, hot melting, mixing, cooling, granulating, pellet cooling to palletizing, the entire system is designed to be intelligent. For example, the batching system adopts multiple continuous loss-in-weight feeders to realize continuous production. The pellet processing system can conduct feeding and convey in a fully automated manner. The high-temperature plastic strands from the extruder can automatically enter a cooling bath for full cooling, before being sent to the automatic conveyor, and then to the pelletizer for granulation.

Most read news

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.