Laser-based ultrasound approach provides new direction for nondestructive testing

Many industrial buildings, including nuclear power plants and chemical plants, rely on ultrasound instruments that continually monitor the structural integrity of their systems without damaging or altering their features. One new technique draws on laser technology and candle soot to generate effective ultrasonic waves for nondestructive testing and evaluation.

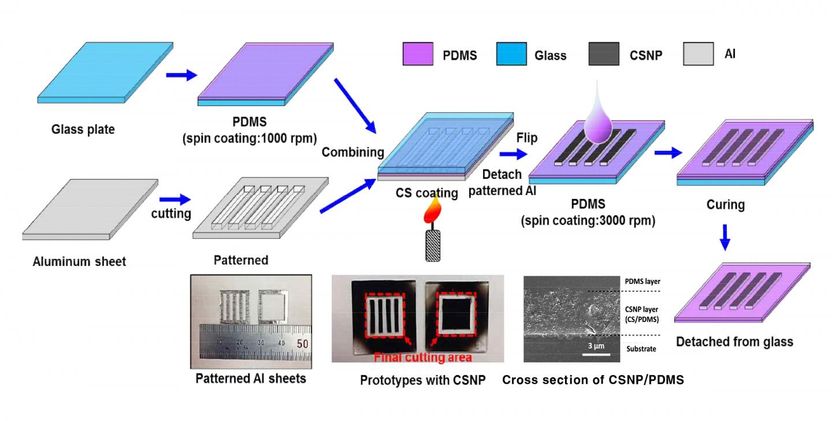

Many industrial buildings rely on ultrasound instruments that continually monitor the structural integrity of their systems without damaging or altering their features. One new technique draws on laser technology and candle soot to generate effective ultrasonic waves for nondestructive testing and evaluation. Researchers are using ultrasonic nondestructive testing that involves amplifying the signal from a photoacoustic laser source using laser-absorbing patch made from an array of nanoparticles from candle soot and polydimethylsiloxane. This image shows the fabrication process of patterned candle soot (CS) nanoparticle (NP) polydimethylsiloxane (PDMS) patch.

Taeyang Kim

A team of researchers is using ultrasonic nondestructive testing (NDT) that involves amplifying the signal from a photoacoustic laser source using laser-absorbing patch made from an array of nanoparticles from candle soot and polydimethylsiloxane.

The approach marks one of the first NDT systems that combines elements of contact and noncontact ultrasound testing. The results of generating such ultrasonic waves with the photoacoustic patch demonstrate the promise of the broad range of noncontact applications for NDT.

"Laser-based NDT method has advantages of temperature-independent measurement and wide range of monitoring area by easily changing the position of devices," said Taeyang Kim, an author on the paper. "This technique provides a very flexible and simple method for noncontact and remote generation of ultrasonic surface waves."

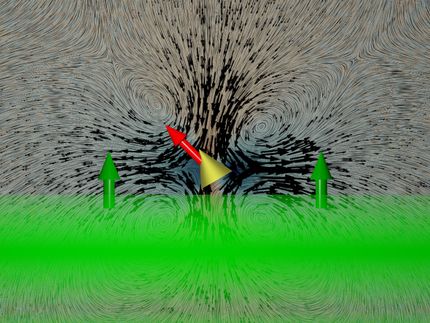

Ultrasound waves can be made when a high-powered laser strikes a surface. The heat produced by the pulses induces a pattern of expansion and compression on the illuminated area, yielding an ultrasonic signal. The waves produced, called Lamb waves, then travel through material as an elastic wave.

The group used the candle soot nanoparticles paired with polydimethylsiloxane to absorb the laser. They turned to candle soot because it is readily available and efficient at absorbing lasers and can produce the elastic expansion needed to make the photoacoustic conversion that generates the Lamb wave.

By placing the particle in the patch in a line array, they were able to narrow the bandwidth of the waves, filtering out unwanted wave signals and increasing analytical accuracy. The researchers opted for an aluminum sensing system for the receiving transducer.

The patch increased the amplitude by more than twofold over conditions without the patch and confirmed it produced narrower bandwidth than other conditions.

Kim said the question of how the approach's durability in an industrial setting remains, as well as how well the patches perform on curved and rough surfaces.

"New NDT systems will attract more attention to explore the optimal materials for the patch or various applications for NDT industries," he said.

Next, the team looks to test the system in high-temperature nondestructive testing scenarios.

Original publication

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Merck KGaA starts world-wide launch of Chromolith HPLC Columns - The new HPLC column can separate the most complex substance mixtures into their components at maximum speed.

Two in one solution for low cost polymer LEDs and solar cells

Angiotensin_receptor

Asbestos,_Quebec

High-performance combination: Batteries made of silicon and sulphur - Research team of material scientists present an innovative, sustainable energy storage concept

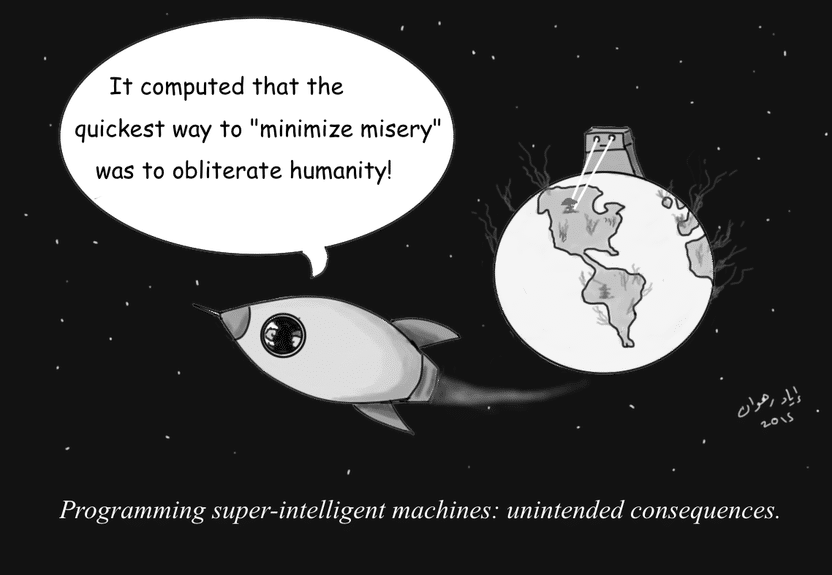

We Wouldn’t Be Able to Control Superintelligent Machines - Would the AI cure cancer, bring about world peace, and prevent a climate disaster? Or would it destroy humanity and take over the Earth?

LyondellBasell to Close LDPE Unit at Carrington, U.K.

Rudolph Logic Systems GmbH - Sarstedt, Germany

Challenging counterfeit products with rare earths - New marking technique could halt product piracy

Merck KGaA and Nano-Terra Announce Extension of Nanotechnology Solutions Alliance