Making More Plastics Recyclable

Advertisement

To date, it is nothing but the wishful thinking of many plastics recyclers: that recyclability is taken into account right from the very beginning of a product’s life cycle, at the product design stage. A new project aims at making this dream come true.

The DIMOP project aims to develop digital tools to easily determine and improve the recyclability of plastic products, for example, by reducing the number of material components.

Jan Werner / SKZ Würzburg

Whether multi-layered food packaging, power cable sheathing or a toothbrush: Many plastic products cannot be recycled. This is the case, for example, when products are made of multiple materials that cannot be separated at all or only insufficiently.

Only 16 percent of plastic waste produced in Germany is also recycled here. This figure is quoted by the Plastikatlas 2019 published by the German Federation for the Environment and Nature Conservation (BUND) and the Heinrich Böll Foundation. The majority of plastic waste is thus burnt in waste incineration plants to generate energy or is used as alternative fuel.

Design and recycling – worlds apart

Making more plastics recyclable: The Chair of Business Administration and Business Information Systems at Julius-Maximilians-Universität (JMU) Würzburg in Bavaria, Germany, has been working towards this goal since July 2019 together with the German Plastics Centre SKZ and two partners from the Bavarian plastics industry. Their project is funded by the Bavarian State Ministry for the Environment and Consumer Protection.

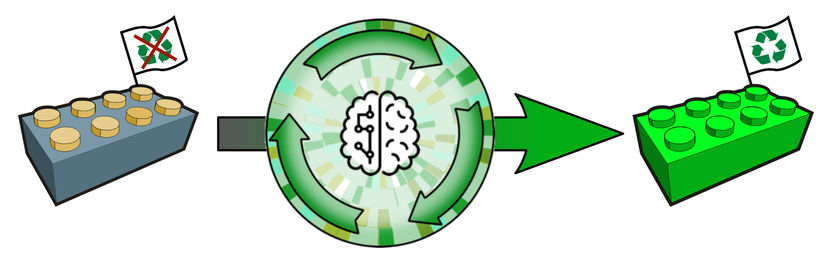

The partners aim at increasing the share of recyclable plastics by reducing the number of material components. "We focus on the product design stage because the recyclability aspect has largely been neglected by designers so far," says Jan Werner from the SKZ, a member of the Zuse society of independent research institutes. "Designers and recyclers live in two completely different worlds; there is no exchange of information." This is why designers often choose materials that are very difficult to recycle.

Digital platform provides information about materials

The project now plans to bring together these two worlds. To achieve this, the scientists want to create a software platform which provides information on the recyclability of different plastics and material combinations. This will enable designers to weigh criteria such as functionality, resource efficiency and recyclability against each other and choose better materials based on this.

A JMU team around Norman Pytel and Professor Axel Winkelmann is in charge of creating this platform. "We want to provide digital tools for product developers to help them make better material choices – always with the aim of increasing the recyclability of plastic products," says PhD student Pytel.

Part of a Bavarian collaborative project to increase resource efficiency

The DIMOP project deals with digital multi-criteria material selection to optimise the recyclability of plastic materials. It is funded by the Free State of Bavaria within the scope of ForCYCLE II, a collaborative project for more resource efficiency in the Bavarian economy, especially in SMEs and handicraft businesses. The project was kicked off in July 2019 and is set to run for three years.