Alternative material investigated for superconducting radio-frequency cavity resonators

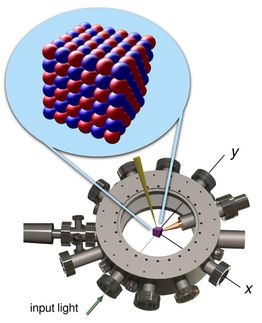

In modern synchrotron sources and free-electron lasers, superconducting radio-frequency cavity resonators are able to supply electron bunches with extremely high energy. These resonators are currently constructed of pure niobium. Now an international collaboration has investigated the potential advantages a niobium-tin coating might offer in comparison to pure niobium.

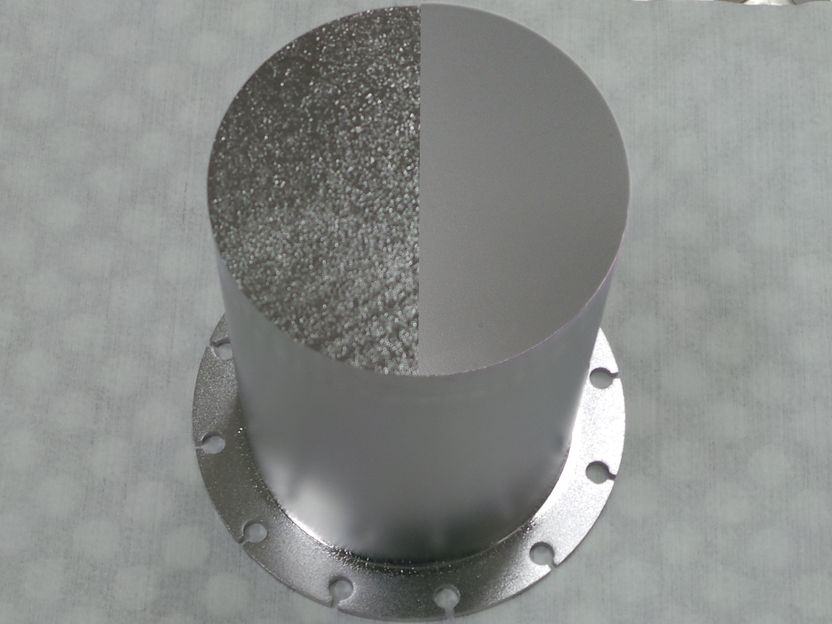

The photomontage shows a sample of solid, pure niobium before coating (left), and coated with a thin layer of Nb3Sn (right).

Copyright: M. Künsting/HZB

At present, niobium is the material of choice for constructing superconducting radio-frequency cavity resonators. These will be used in projects at the HZB such as bERLinPro and BESSY-VSR, but also for free-electron lasers such as the XFEL and LCLS-II. However, a coating of niobium-tin (Nb3Sn) could lead to considerable improvements.

Coatings may save money and energy

Superconducting radio-frequency cavity resonators made of niobium must be operated at 2 Kelvin (-271 degrees Celsius), which requires expensive and complicated cryogenic engineering. In contrast, a coating of Nb3Sn might make it possible to operate resonators at 4 Kelvin instead of 2 Kelvin and possibly withstand higher electromagnetic fields without the superconductivity collapsing. In the future, this could save millions of euros in construction and electricity costs for large accelerators, as the cost of cooling would be substantially lower.

Experiments in the USA, Canada, Switzerland and HZB

A team led by Prof. Jens Knobloch, who heads the SRF Institute at HZB, has now carried out tests of superconducting samples coated with Nb3Sn by Cornell University, USA, in collaboration with colleagues from the USA, Canada, and Switzerland. The experiments took place at the Paul Scherrer Institute, Switzerland, at TRIUMF, Canada, and the HZB.

“We measured the critical magnetic field strengths of superconducting Nb3Sn samples in both static and radio-frequency fields”, says Sebastian Keckert, first author of the study, who is doing his doctorate as part of the Knobloch team. By combining different measurement methods, they were able to confirm the theoretical prediction that the critical magnetic field of Nb3Sn in radio-frequency fields is higher than that for static magnetic fields. However, the coated material should display a very much higher critical magnetic field level in a radio-frequency field. Thus, the tests have also shown that the coating process used currently for the production of Nb3Sn might be improved upon in order to more closely approach the theoretical values.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents