Modified 'white graphene' for eco-friendly energy

Scientists found a way how to use 2D material for hydrogen energy

Scientists from Tomsk Polytechnic University (TPU), Germany, and the United States have found a new way to functionalize a dielectric, otherwise known as 'white graphene', i.e. hexagonal boron nitride (hBN), without destroying it or changing its properties. Thanks to the new method, the researchers synthesized a 'polymer nano carpet' with strong covalent bond on the samples.

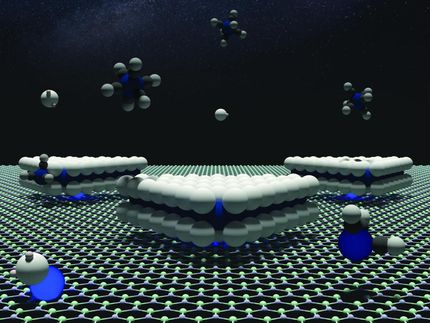

This is a catalyst with functionalized hexagonal boron nitride and nickel nanoparticles.

Tomsk Polytechnic University

Prof Raul Rodriguez from the TPU Research School of Chemistry & Applied Biomedical Sciences explains: 'For the first time, we have managed to covalently functionalize hexagonal boron nitride without strong chemical compositions and the introduction of new defects into the material. In fact, earlier approaches had resulted in a different material with altered properties, i.e. hydrolyzed boron nitride. In our turn, we used nanodefects existing in the material without increasing their number, and eco-friendly photopolymerization.'

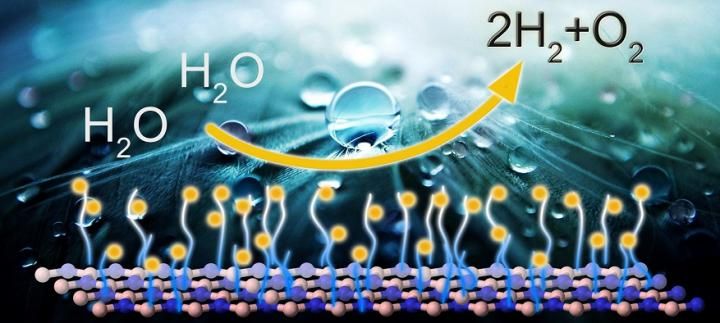

One of the promising options for using the new material, according to researchers, is catalysts for splitting water in hydrogen and oxygen. With this in view, 'polymer carpets' functioned as carriers of active substances, i.e. matrices. Nickel nanoparticles were integrated into the matrix. Catalysts obtained were used for electrocatalysis. Studies showed that they could be successfully used as an alternative to expensive platinum or gold.

'One of the important challenges in catalysis is forcing the starting material to reach active centers of the catalyst. 'Polymer carpets' form a 3D structure that helps to increase the area of contact of the active centers of the catalyst with water and makes hydrogen acquisition more efficient. It is very promising for the production of environmentally friendly hydrogen fuel,' - says the scientist.

Boron nitride is a binary compound of boron and nitrogen. While, hexagonal boron nitride or 'white graphene' is a white talc-like powder with hexagonal, graphene-like lattice. It is resistant to high temperatures and chemical substances, nontoxic, has a very low coefficient of friction, and functions both as a perfect dielectric and as a good heat conductor. Boron-nitride materials are widely used in the reactions of industrial organic synthesis, in the cracking of oil, for the manufacturing of products of high-temperature technology, the production of semiconductors, means for extinguishing fires, and so on.

Previously, a number of studies were devoted to functionalization of hexagonal boron nitride. Typically, this process uses strong chemical oxidants that not only destroy the material but also significantly change its properties. The method, which TPU scientists and their foreign colleagues use, allows them to avoid this.

'Studies have shown that we obtained homogenous and durable 'polymer carpets' which can be removed from the supporting substrate and used separately. What is more, this is a fairly universal technology since for functionalization we used different monomers which allow obtaining materials with properties optimal for use in various devices,' - says Prof Raul Rodriguez.

Original publication

Topics

Organizations

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.