BP, Nouryon and Port of Rotterdam partner on green hydrogen study

BP, Nouryon (formerly AkzoNobel Specialty Chemicals), and the Port of Rotterdam have joined forces to explore the opportunity of making ‘green hydrogen’ via water electrolysis for BP’s refinery in Rotterdam, the Netherlands, which has the potential for significant reductions in CO2 emissions.

BP’s refinery in Rotterdam

The refinery currently uses hydrogen made from hydrocarbons, to desulphurize products. Replacing this entirely with green hydrogen produced from water using renewable energy could potentially result in a reduction of 350,000 tons of CO2 emissions per year based on current circumstances.

The parties have signed a memorandum of understanding to study the feasibility of a 250-megawatt water electrolysis facility to produce up to 45,000 tons of green hydrogen yearly using renewable energy. It would be the largest of its kind in Europe.

Nouryon would build and operate the facility based on its leadership position in sustainable electrochemistry. The Port of Rotterdam would facilitate local infrastructure and investigate options for further development of a green hydrogen hub in the area. The partners intend to take a final investment decision on the project in 2022.

Ruben Beens, CEO of BP Netherlands said: “BP is committed to advance a low carbon future. We have committed to reduce emissions in our operations, improve our products to help customers reduce their emissions and create low carbon businesses. The use of green hydrogen, made from water with renewable energy, has the potential to deliver significant emissions reductions at Rotterdam. Working with Nouryon and the Port of Rotterdam will allow us to explore and fully understand the technical, operational and financial dimensions of this potential opportunity.”

Knut Schwalenberg, Managing Director Industrial Chemicals at Nouryon, added: “This partnership builds on our expertise in electrolysis technology to open up new value chains. With green hydrogen, we can provide sustainable solutions to our customers ranging from low-carbon fuels and industrial processes to new forms of circular chemistry.”

Allard Castelein, CEO of the Port of Rotterdam, commented: “Development of large-scale electrolysers connected to offshore wind farms is vital for making solid progress with the new energy system in order to realize our climate goals. This 250-megawatt electrolyser is a key proof point that Rotterdam has the ability to be a frontrunner in the energy transition, which is an important differentiator for the port industry.”

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Albemarle to Increase Price of SAYTEX(R) BT-93W and BT-93 Brominated Flame Retardants

Catalytic converter with a green profile

Carl Zeiss Foundation donates EUR 850,000 to the Advanced Lab for Electrochemistry and Electroorganic Synthesis - Research structure concept of ELYSION enhances the relevance in the fields of electroconversion and electroactive materials

A. Schulman Names Todd Nichols Sales Manager for its Engineered Plastics, North America Business Unit

SABIC Europe to increase prices for PP Automotive grades

Palladium use in diesel emission control systems for cars now a reality

PPG Completes Acquisition of Dyrup

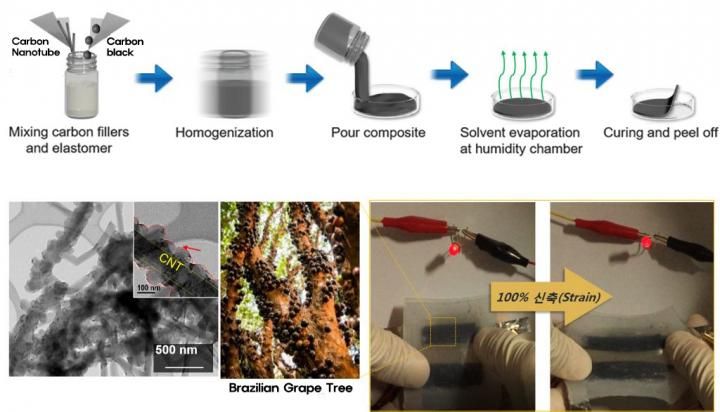

Highly stretchable aqueous batteries developed

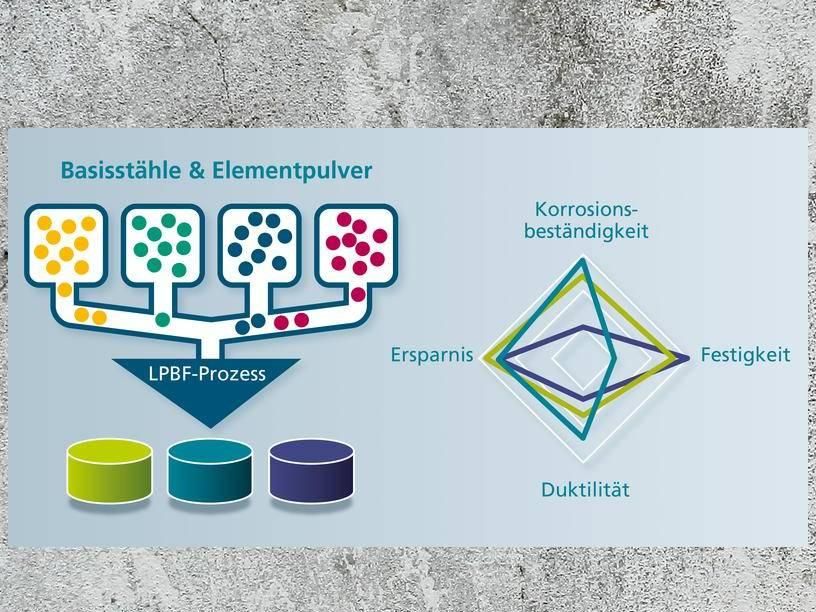

Materials by recipe - Powder kit for more flexibility and material diversity in 3D printing

SABIC Innovative Plastics Wins 2007 National Energy Globe Award for Brine Recovery Project at Bergen op Zoom Facility

World's tiniest mirror