High-performance combination: Batteries made of silicon and sulphur

Research team of material scientists present an innovative, sustainable energy storage concept

Longer lifetimes, larger ranges and faster recharging - developments such as electric mobility or the miniaturisation of electronics place new requirements on rechargeable batteries. With its enormous storage capacity, silicon has decisive advantages over the materials used in commercially available lithium-ion batteries. A research team from the Institute for Materials Science at Kiel University, in cooperation with the wet-chemistry manufacturer RENA Technologies GmbH, has developed high-performance silicon anodes. Combined with sulphur cathodes they could reach an energy density twice to three times higher, up to 90 percent shorter charging time and 20 percent lower weight. In addition to electric mobility, the new battery concept could be used for applications as mobile phones, shipbuilding or stationary and temporary storage for solar and wind power installations.

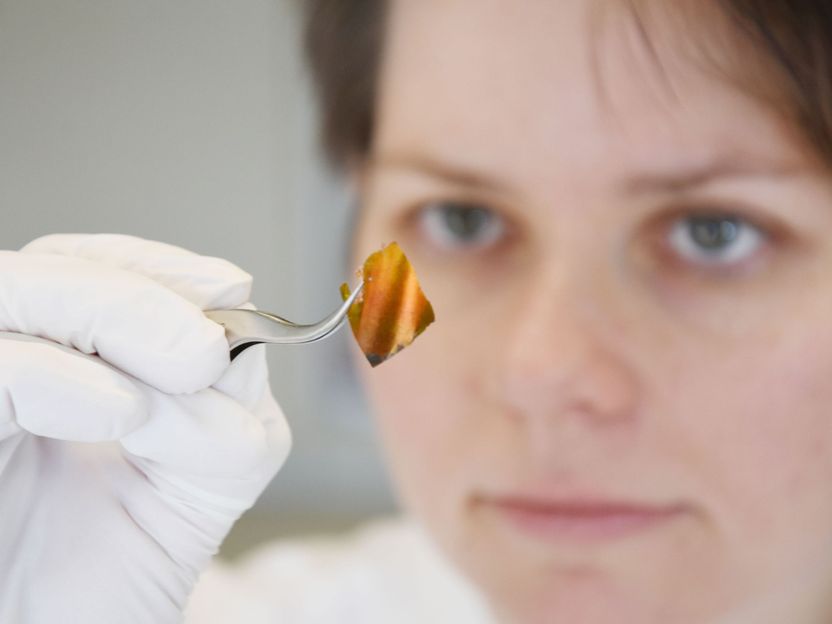

A new generation of rechargeable batteries: Die research team develops wafer-thin anodes out of silicon that is able to store a lot of energy.

© Julia Siekmann, Uni Kiel

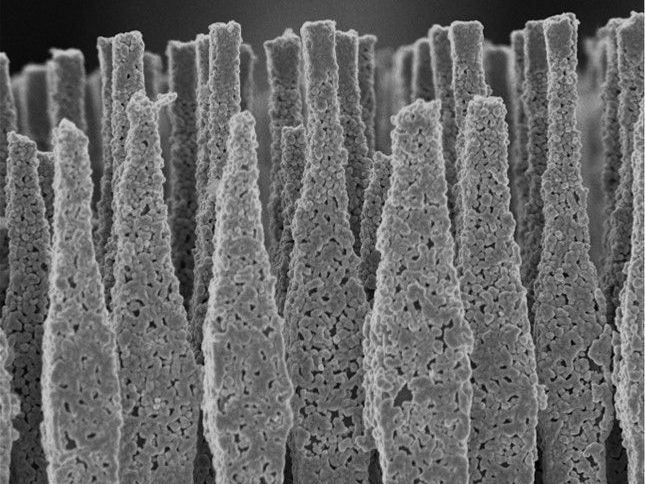

When charging the battery, silicon expands by 400 percent, and the delicate material could break. It is much more flexible in the form of such micro-wires, as Hansen was able to prove in her doctoral thesis.

© Sandra Hansen

Due to the especially high energy density of silicon electric cars could drive further, the batteries of mobile phones could last longer, recharge faster and would be hardly inflammable. “But so far the semiconductor was too sensitive to use it in rechargeable batteries on a large scale”, says material scientist Dr Sandra Hansen. During charging, lithium ions move back and forth between the anode and cathode. Since Silicon can take up a remarkable number of lithium ions, it expands by 400 percent, and would break in the long run.

With a project funded by the German Federal Ministry of Education and Research (BMBF) a research team around Hansen, together with Rena Technologies GmbH, is working on developing high-performance silicon anodes combined with sulphur cathodes and a concept for manufacturing them on an industrial scale. By the precise structuring of its surface at the micro level, they already managed to produce silicon in the form of a thin wire. „This way silicon is more flexible and can withstand the high volume expansion when charging”, says Hansen. But until now the fabrication of the wires is highly expensive. For a cost-efficient production without additional process steps Hansen and Rena Technologies developed the anodes out of highly porous silicon. They have a similar effect and are currently tested in first full cells.

These silicon anodes can be customized developed for individual requirements. Another material with very high storage potential forms the counterpart with a sulphur cathode. This is how the storage potential of silicon can be fully exploited. But NMC cathodes of traditional lithium-ion batteries are also compatible with the developed silicon anodes.

Thanks to the cooperation with industry, the research results flow directly into the development of new etching systems. „At the moment we are looking for more partners from industry and science to develop batteries for individual applications”, says Hansen. “We are particularly interested in expertise and infrastructure on electrolyte systems for sulphur-air, lithium-sulphur, lithium-air and lithium-ion technology.” As the future leader of a battery lab that is currently under construction at the Faculty of Engineering at Kiel University, she wants to upscale silicon anodes and sulphur cathodes to produce prototypes, adjusted to the certain requirements of companies.

From 1 to 5 April 2019, Dr Sandra Hansen and her team will be presenting the concept, fabrication and application of silicon anodes and sulphur cathodes at the Kiel University booth at the Hannover Messe.

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.