Indestructible Plastic: Ceresana Analyzes the Global Market for PVC

Sunlight, acid or salt water: polyvinyl chloride (PVC) can withstand practically anything and is almost indestructible. PVC plasticizers are controversial, yet, this robust material remains one of the most frequently produced plastics alongside polypropylene and polyethylene. Demand even continues to increase: The most current and already fifth PVC market report by Ceresana expects demand to increase to about 56.2 million tonnes until 2026.

Hard and Soft, Rigid and Flexible

A distinction is made between rigid PVC (rigid PVC-U = unplasticized), which is used, for example, for packaging, pipes, and window profiles, and flexible PVC (flexible PVC-P = plasticized), which contains up to 40% plasticizer and is used for elastic products. PVC-U accounts for approximately two thirds of total demand. In 2018, pipes and conduits reached a market share of over 37%. Profiles (19.9%) and films and sheets (18.3%) follow at a distance. PVC is also used for cables, flooring, and containers. The diverse other applications include, for example, coatings, medical products such as infusion bags, shoes, and credit cards.

Sewage, Potable Water, and Industrial Pipes

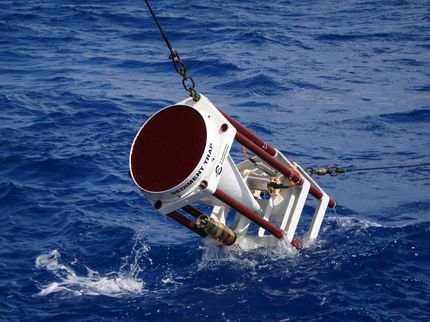

The material PVC offers significant advantages for the production of sewage pipes: Compared to pipes made of concrete or metal, the weight of the units to be laid is drastically reduced. PVC is very resistant to corrosion and numerous chemicals. The shape of PVC pipes becomes more and more variable as well. Non-circular pipes, for example, are suitable for relining old drainage pipelines which often have non-circular shapes. In 2018, over 7 million tonnes of PVC were processed into sewage pipes. The market for potable water pipes is slightly smaller. In highly developed industrial countries in particular, legal requirements regarding potable water pipelines are often very high. A positive characteristic of PVC pipes is their resistance against UV radiation, chlorine, and ozone.

Construction Industry Ahead of Packaging Manufacturers

With a share that is likely to exceed 60%, the construction industry will be the most important customer for PVC producers also in the years to come. Examples for the use in the construction industry are: films, cables, tubes, profiles and coverings, sheets and pipes, dowels, screws, mounting elements, and coatings. The packaging industry will rank second with almost 16%, using PVC for flexible and rigid packaging. The most important application areas in this sector are packaging films, bags and sacks as well as shrink and stretch films. The rigid packaging segment includes containers such as butter and margarine tubs, yogurt cups, bottles, boxes as well as caps.

Most read news

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.