Ceresana Announces New Study on EPS: Ascent of a Climate Protector

Building insulation provides an effective way to save a good deal of money and also protect the environment. 23 million homes are in need of insulation improvement in Germany alone: if their heat insulation was updated to the newest standards, heating oil consumption could be cut by 83 billion liters, and CO2 output would fall by 250 million tons per year. The savings potential is even greater in countries with warmer climates, since air conditioning systems require a considerable amount of energy. This provides a good outlook for manufacturers of EPS, the most important insulation material. Ceresana, the market research institute, is releasing a new study covering expandable polystyrene.

Roughly two-thirds of EPS demand is accounted for by blocks and panels in the construction industry, the largest application area. The construction industry's importance will continue to grow: many governments, particularly in Europe, are promoting measures to increase energy efficiency. Therefore Ceresana Research expects to see continued growth in EPS consumption starting in 2010, despite declining building sectors in many locations. After worldwide EPS revenue had increased at an average rate of 7.3% per year between 2000 and 2008, it fell to approximately 4.3 billion € in 2009. “Due to substantial price decreases, revenue fell by up to a third in some world regions“, says Oliver Kutsch, owner of Ceresana Research. “However, prices are already starting to rise again. We expect market value will reach the level from 2008 again in 2012.“

Aside from heat insulation, used for example in boilers and entire tanker ships, EPS is primarily applied where shock absorbance and sound insulation is required. The small foam pellets can be found in products, such as protective helmets for cyclists, electronics packaging and sound baffles. Since the material is harmless, it is also used for disposable cups and other food containers. EPS is very buoyant because it consists of up to 98 percent air, and is used for lightweight cores in surfboards, life jackets, and life-savers. Simple and almost arbitrarily moldable EPS is utilized in the production of architectural models, as well as theater backdrops and decorations. Lesser known technical applications of EPS include for example, void formers for iron or aluminum parts in motors.

EPS production is particularly dynamic in Eastern Europe and the Asian Pacific. Ceresana Research expects to see growth there until 2016, in the amount of 7.1 and 5.9 percent per year, respectively. China alone, which is already the world's largest EPS manufacturer, should see capacities increase by more than 750,000 tons, while East European countries should see a growth of just less than 350,000 tons. In contrast, EPS production in Japan and South Korea will most likely fall.

Organizations

Related link

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

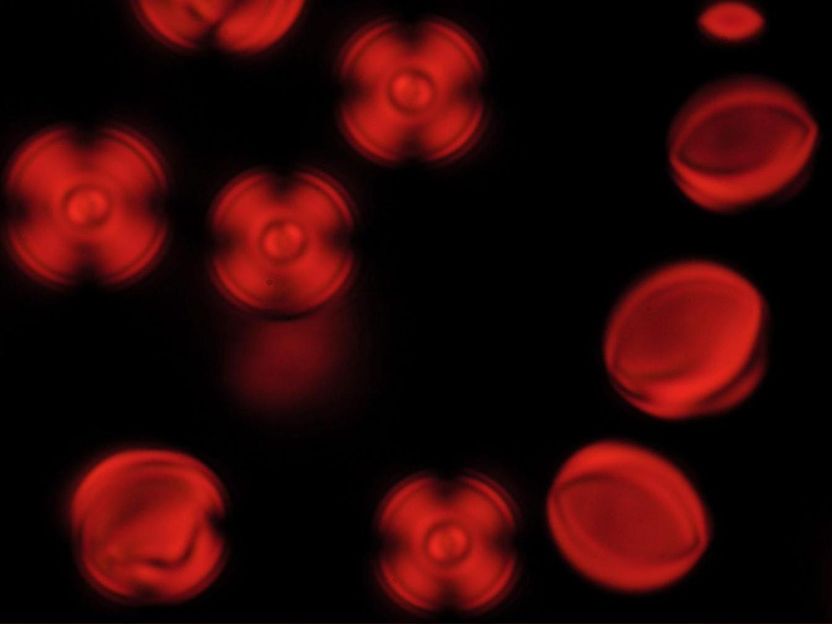

Surprising twist in confined liquid crystals - A simple route to developing new sensors

HYDROTHERM | Acid hydrolysis systems | C. Gerhardt