Researchers develop a solid material with mobile particles that react to the environment

Advertisement

Inside most materials, little is moving. But a new “active nanocomposite” is teeming with motion: small particles connect or separate, thus changing the color of the entire material. It was made by scientists of the Leibniz Institute for New Materials in Saarbrücken in an attempt to lend materials more dynamics. The transparent material can “answer” temperature changes or, in the future, the presence of chemical substances and toxins with a color change. The researchers want to create packaging films that change their color when food spoils, for example.

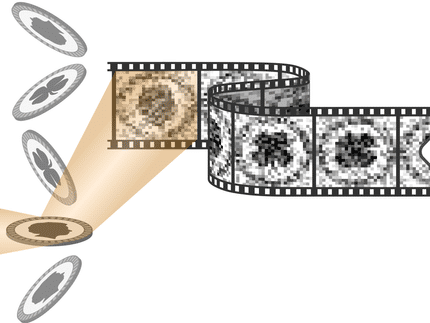

At high temperatures (left) particles move freely in the droplets and lend the material a ruby red color; they agglomerate at lower temperatures (right) and change the material’s color to grey-violet.

INM

How does one get solid particles to move inside a solid material? „You rarely want this to happen in steel, concrete, or plastics, because free motion usually implies a weak spot in the material. In our active nanocomposites, particles are decoupled from the main material inside small compartments, while the rest remains stable,” says Tobias Kraus, Head of the Structure Formation Group at INM.

The research team used a trick: like raisins in a pudding, they distributed small liquid droplets in a polymer. The droplets contained gold nanoparticles that move freely inside each droplet, something they could not do in the solid: “The particles are now free to either agglomerate or freely move in the entire droplet. The nanocomposite’s color depends on how far the nanoparticles are from each other, it changes from ruby red to grey-violet in our example. The particles can separate again, and the color change is fully reversible,” explains Professor Kraus.

The naked eye can discern neither the droplets nor the nanoparticles inside. The entire composite is translucent; it simply changes its color depending on temperature. “The result is relevant for applications that require transparent materials. We envision coating it onto clear films, for example,” says the material scientist Kraus.

In the current publication, the particles agglomerate depending on temperature. In the future, the scientists want the nanocomposite to react to chemical stimuli. „One may use this to directly visualize high Vitamin C concentrations or toxins, for example,” ponders Kraus.