Nanoscale measurements 100x more precise, thanks to improved two-photon technique

Technique uses photons, fundamental components of light, to measure nanoscopic materials thinner than 100,000th the width of a human hair - with 30,000 fired per second and 500bn throughout Research will mean measurements 100x more precise than existing two-photon techniques - with the potential to aid research into cell membranes and DNA Two-photon technique more stable than existing one-photon technology New technique could also be substantially cheaper

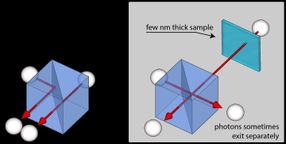

Artist's impression of photons entering beamsplitter, as per the technique.

University of Warwick

Diagram showing the technique for measuring nanoscopic structures.

University of Warwick

The precision of measuring nanoscopic structures could be substantially improved, thanks to research involving the University of Warwick and QuantIC researchers at the University of Glasgow and Heriot Watt University into optical sensing.

QuantIC is the UK Quantum Technology Hub in Quantum Enhanced Imaging and part of the UK National Quantum Technologies Programme.

Using pairs of photons, fundamental components of energy that make up light, the researchers have devised a way to measure the thickness of objects that are less than a 100,000th of the width of a human hair.

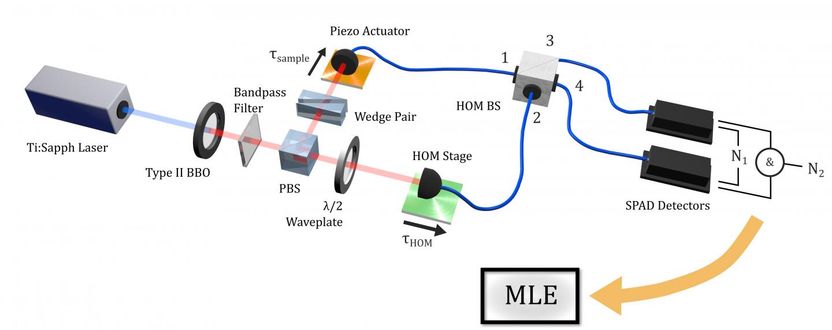

The new technique involves firing two near identical photons onto a component known as a beamsplitter, and monitoring their subsequent behaviour - with some 30,000 photons detected per second, and 500bn in use throughout a full experiment.

Because of the tendency of identical photons to 'buddy up' and continue travelling on together -- the result of a delicate quantum interference effect - the researchers' newly developed setup offers the same precision and stability as existing one-photon techniques that, due to the equipment required, are more costly.

Offering a range of potential uses, including research to better understand cell membranes and DNA, as well as quality control for nanoscopic 2D materials of a single atom's thickness, such as graphene, the new research is also a marked improvement on current two-photon techniques with up to 100x better resolution.

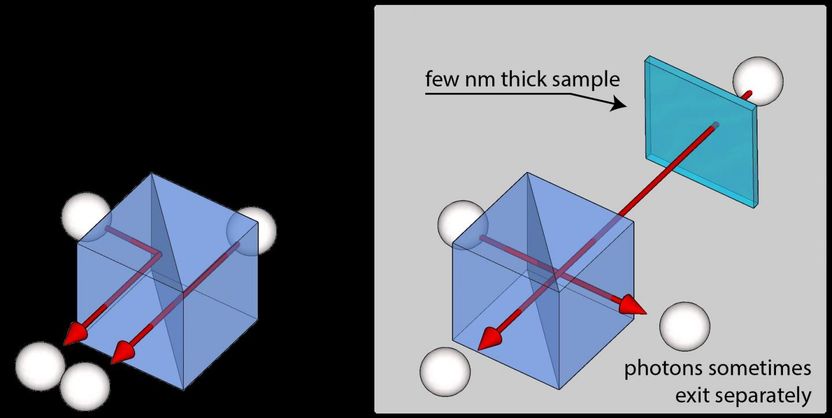

To measure the thickness of a transparent object (any object through which a photon is able to pass), each of a pair of identical photons are fired along separate paths:

Photon A then continues into a beamsplitter, whilst Photon B is slowed down by a transparent object before entering the same beamsplitter. The likelihood that the photons exit the beamsplitter together is then recorded allowing researchers to measure the thickness of the transparent object Photon B passed through.

As the thickness of the sample is increased, the photons are more likely to exit the beamsplitter separately.

Dr George Knee of the University of Warwick's Department of Physics, who developed the theory behind the new method, said:

"What's really exciting about these results is that we can now investigate objects down at the nanoscale with an optical sensor operating on a fundamentally different physical effect.

"Until now, so-called two-photon interference has not been able to achieve such great resolution, meaning that we are stuck with some of the downsides of the established methods based on single-photon interference - which requires more expensive technology than our new two-photon technique.

"We have managed to get a big improvement by tuning the interferometer into a more sensitive operation mode and removing slow drift by repeatedly switching the sample in and out.

"The advantages of being impervious to phase fluctuations and having large dynamic range mean that sensors such as ours could have a big impact on biological imaging and the associated research that it feeds into."

QuantIC co-investigator and lead researcher on the project, Professor Daniele Faccio, whose two photon sensing technology was used to generate the data said:

"The results of our collaboration with the University of Warwick offer a range of potential uses, including research to better understand cell membranes and DNA as well as a quality control for nanoscopic 2D materials of a single atom's thickness, such as graphene.

We are excited to be advancing quantum imaging and helping to maintain the UK's position in the development of new quantum technologies."

Original publication

Lyons, Ashley and Knee, George C. and Bolduc, Eliot and Roger, Thomas and Leach, Jonathan and Gauger, Erik M. and Faccio, Daniele; "Attosecond-resolution Hong-Ou-Mandel interferometry"; Science Advances; 2018

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.