Newly improved glass slide turns microscopes into thermometers

The humble glass microscope slide may be primed for a makeover.

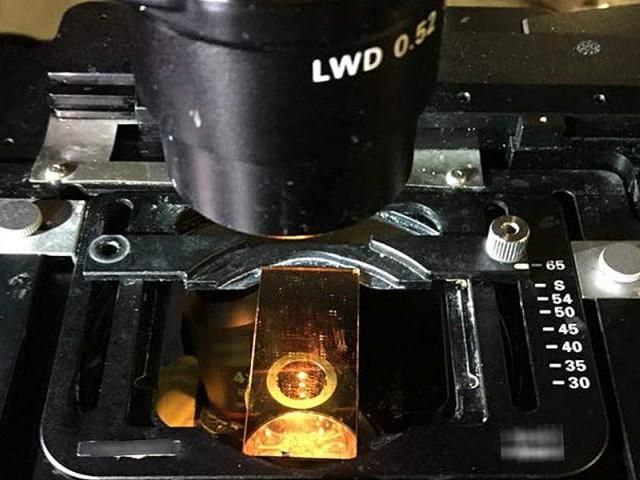

A photo of the experiment using a glass slide with the new coating.

University at Buffalo

A study published online in the journal Nature Communications describes how an updated version of this centuries-old tool can now enable scientists to see tiny objects while also measuring their temperature.

The advancement, made possible by a new transparent coating at the forefront of optics theory, has the potential to streamline and enhance scientific research worldwide, from clandestine government biology labs to high school chemistry classes.

It may also have implications in other industries, such as computers and electronics, whose products require measurement and control of heat in highly confined spaces.

"We have instruments that magnify incredibly small objects. And we have tools that measure heat, like infrared thermometers. But we haven't been able to combine them in a low-cost and reliable manner. This new coating takes a big step in that direction," says the study's co-lead author Ruogang Zhao, PhD, assistant professor in the University at Buffalo Department of Biomedical Engineering.

The department is a multidisciplinary unit formed by UB's School of Engineering and Applied Sciences and the Jacobs School of Medicine and Biomedical Sciences at UB.

Zhao collaborated with researchers at the University of Pennsylvania, including co-lead author Liang Feng, PhD, assistant professor of materials science and engineering, and electrical and systems engineering.

For decades, researchers have tried to combine thermal imaging and microscopy. Images produced from systems that use thermocouples lack resolution and are often too coarse for modern science. Terahertz and infrared thermal mapping techniques interfere with the microscope's lenses. Other techniques are expensive and time-consuming.

The new coating is made of a layer of acrylic glass (the same material used in most eyeglasses) that's sandwiched between two layers of transparent gold. The gold is transparent because it's only 20 nanometers thick; a typical sheet of paper is 100,000 nanometers thick.

Engineers fabricated the coating so that "exceptional points" -- the sweet spots where unusual light behavior happens -- can develop within the tri-layered structure. The coating, which significantly enhances the slide's sensitivity to light detection, would be added to slides during the manufacturing process. Either the slide or cover slip could receive the coating.

To make use of the new coating, a laser is needed. Zhao says a common helium-neon laser, which can be seamlessly integrated with most microscopes, will do the job.

Common slides, which are often bought in bulk, typically cost around 5 cents. The new coating would likely add a few pennies to the cost, Zhao says.

Original publication

Han Zhao, Zhaowei Chen, Ruogang Zhao & Liang Feng; "Exceptional point engineered glass slide for microscopic thermal mapping"; Nature Communications; Volume 9, Article number: 1764 (2018)

Most read news

Original publication

Han Zhao, Zhaowei Chen, Ruogang Zhao & Liang Feng; "Exceptional point engineered glass slide for microscopic thermal mapping"; Nature Communications; Volume 9, Article number: 1764 (2018)

Organizations

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.