Evaluating risk of hydrogen embrittlement

New simulation of cold cracks in high-strength steels

High-strength steels play a vital role in the construction of modern vehicles and machines. If these steels are welded during the production of components, mobile hydrogen atoms can cause problems within the material: the atoms accumulate slowly at highly stressed areas of a component, resulting in the steel becoming brittle at these locations. This can result in so-called cold break formations which can lead to component failure. Dr. Frank Schweizer of the Fraunhofer Institute for Mechanics of Materials IWM has developed a simulation method with which component manufacturers can assess cold break tendencies and adjust their production accordingly.

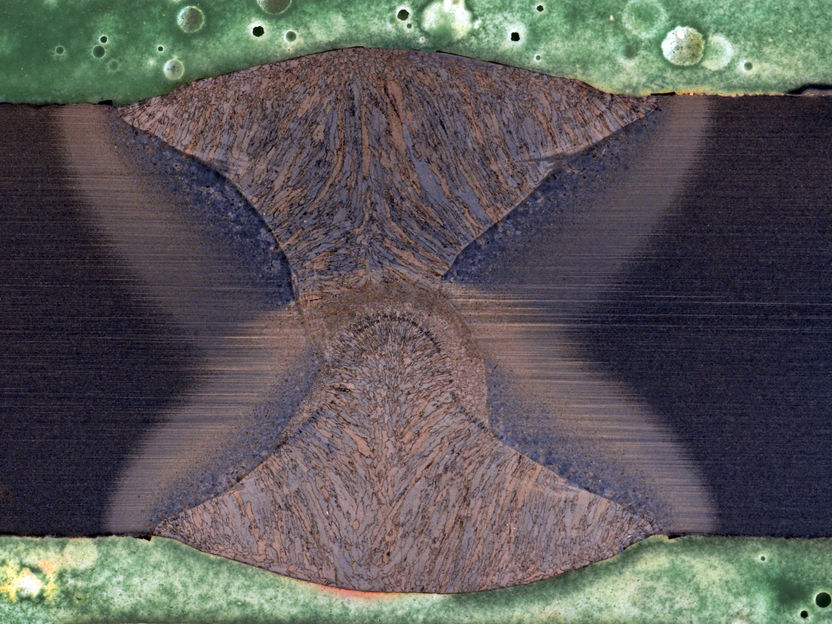

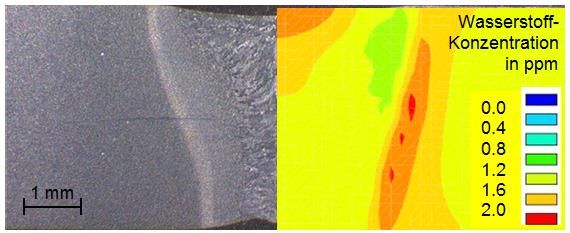

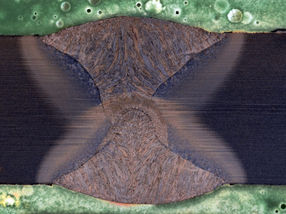

Light microscopy image of a welded connection’s weld structure

© Fraunhofer IWM

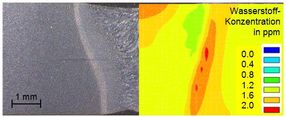

The new simulation method helps optimize laser welding processes: light microscopy image of laser welded connection’s weld structure (left) compared to the calculated locally diffusible hydrogen concentration depending on temperature-time-development and welding residual stress (right).

© Fraunhofer IWM

Manufacturers of vehicle and machine components often use high-strength steels to save material in lightweight construction and for crash-relevant structural components that require exceptionally high durability. When welding these components, various factors may lead to the unwanted formation of fine cracks, which may spread and even lead to component failure. Unfortunately it is very hard or impossible to assess these factors with experiments, for example hydrogen concentration would have to be measurable in highly localized points inside the component during welding. Another difficulty: the period of time during which a break may forms is relatively long – it can form within seconds during the welding process or after a few days. This is why the reject rate of laser welded high-strength steel components to this day remains uncomfortably high.

Illustrating the influence of hydrogen traps

To enable component manufacturers to reduce the reject rate of high-strength steels, Dr. Frank Schweizer, a member of the »Microstructure, Residual Stress« group at the Fraunhofer IWM, refined industrially used methods of numerical welding simulation in his dissertation. Now he can recreate any events at highly localized component points on his computer. This even functions for very quick changes between room and melting temperatures, as they occur during welding. »Now we can calculate the temporal development of influencing factors and their intersections accurately and monitor them virtually«, explains Schweizer. These factors include hardening structures, residual stress and localized hydrogen concentration, which can lead to crack formation in the welded component. Alongside the hydrogen which is introduced during the welding process, previously existing hydrogen in the steel is loosened up by the welding heat and rendered movable and diffusible.

»The special feature of this new method is that it also takes into account the effect of so-called hydrogen traps«, says Schweizer. He discovered that hydrogen traps greatly influence the »movable« hydrogen occurring in low hydrogen concentration for different laser welding connections. With higher hydrogen content the thermomechanical behavior of the material grows more relevant for the formation of breaks. »The hydrogen atoms slowly collect in the narrow area of the heat-affected zone where tensile residual stress is especially high«, says Schweizer. Even after the steel has cooled down, hydrogen can collect at these points and the steel grows brittle. »Thus even after hours or days cracks may form which must lead to the component’s rejection«, explains Schweizer.

Simulation as basis for optimization of laser welding process

Simulation results are the basis for optimizing laser welding processes and sustainably preventing component failure: »Now the laser process parameters can be adjusted to keep interactions of cold crack risk factors as low as possible«, says Schweizer. More precise pre-heating and post-heating temperatures, as well as custom-fit annealing durations can be determined from simulations. »During the planning of components a simulation is useful as well: Following the data, better component shapes can be deduced to improve local stress points and avoid cracks«, explains Schweizer. In the next step of his research, Schweizer wants to examine the influence of various materials and component surfaces on the so-called effusion of hydrogen more closely in order to more precisely interpret pre-heating and post-heating procedures in the future. Furthermore he will use this new methodology on more steels and different welding procedures.

As a data basis for Schweizer’s expanded numerical welding simulations, characteristic material values of three different high-strength steels were used: bearing steel, martensitephase steel and fine-grained steel. Characteristic material values were calculated experimentally as well as using both new and his own numerical evaluation methods. Schweizer tested his simulation models successfully in three industrially used components which were joined using different welding procedures: heat conduction welding as well as deep welding via fiber lasers and CO2 lasers.