VTT has developed a fully recyclable coating for food & pharmaceuticals

VTT Technical Research Centre of Finland has developed an environmentally-friendly packaging coating solution. Especially suitable for food and pharmaceutical packaging, the coating offers a new method for manufacturing fully recyclable, thin, light and air-tight packaging materials.

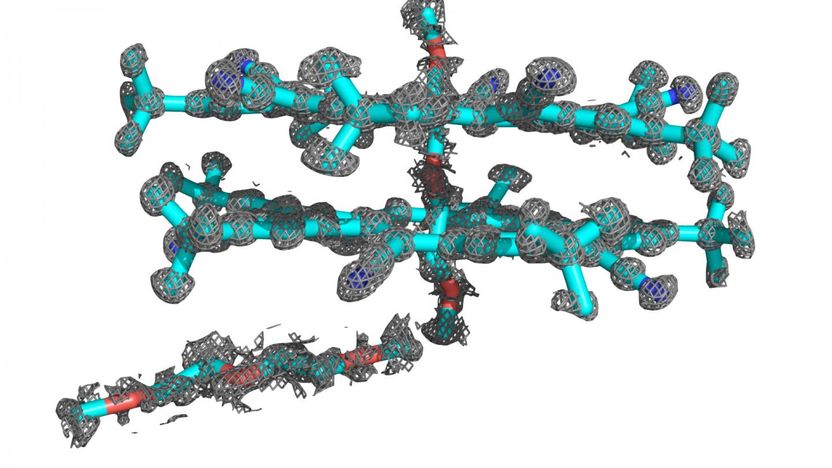

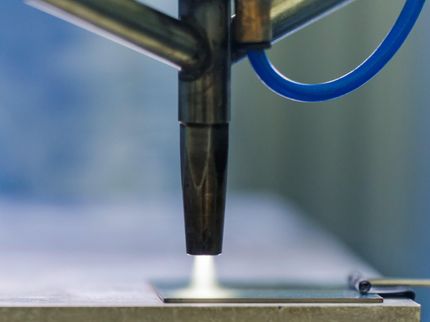

Developed using the atomic layer deposition (ALD) method, the coating has excellent gas permeation resistance and as such it is particularly suitable for food and pharmaceutical products. The ALD technology, which was developed in Finland in the 1970s, has been utilised mainly in microelectronics to date. ALD facilitates the manufacture of packaging materials which are thinner, lighter and better sealed than traditional barrier materials. Barrier materials have the ability to prevent molecules from penetrating the packaging, which is important when protecting the product from humidity, drying or oxidation.

The barrier ability can be created without an aluminium film, the traditional barrier material which affects recyclability. For packaging technology, this creates an opportunity to manufacture fully recyclable packages that use fewer raw materials. The amount of aluminium can be reduced 500-1,000-fold compared to current medicine blister packs. The use of aluminium affects the pack’s recyclability, and its manufacture requires a lot of energy.

ALD coatings are thin, conformal and pinhole-free and they closely follow the contours of the coated material. Their thickness can be adjusted to the accuracy of one atomic layer. Thanks to the thinness of the film (approx. 25 nanometres), the protective layer is bendable and flexible. Thin bio-based packaging materials produced using this technology have gas permeability properties similar to those of existing dry food packages and pharmaceutical blister packs.

By using ALD coating, different functions can be integrated in the packaging material, such as properties which prevent water, oxygen, humidity, fats and aromas from permeating the packaging and protect the surface from stains and bacterial growth. ALD thus provides savings on raw material and transport costs, as the amount of packaging material can be reduced. For example, chocolate wrappers can now be made without the aluminium-coated paper, if the carton wrap is treated with the ALD coating method.

Other thin film methods can also produce thin coatings; however, their gas permeability is higher and the material is stiffer and breaks easily. With these competing methods, comparable gas permeation resistance is possible only if thicker films are used.

The ALD technology can improve the humidity tolerance and performance of bio-polymers, reducing the need for oil-based plastics

Most read news

Topics

Organizations

Other news from the department research and development

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Ascenion coaches spin-off from the Helmholtz Zentrum München - eADMET to Improve Drug Discovery and Development Drugs

FIU scientists discover how arsenic builds up in plant seeds

Stanford-SLAC team uses X-ray imaging to observe running batteries in action

A new ISO 9001:2008 for Altmann Analytik by TÜV Süd

Hte AG and Elevance Renewable Sciences Announce Research Collaboration - Companies Collaborate in the Development of Bio-Based Specialty Chemicals

Recyclates: Recycled Materials as the Next Step Towards Increased Sustainability for High-End Laboratory Consumables - Disposable racks made from contact lens production leftovers

Arkema launches an industrial production project in Europe of a low-GWP* fluorinated gas for automotive air-conditioning