How biofuels from plant fibers could combat global warming

Scientists, companies and government agencies are hard at work on decreasing greenhouse gas emissions that cause climate change. In recent years, biofuels produced from corn have emerged as a fuel source to power motor vehicles and, perhaps, airplanes.

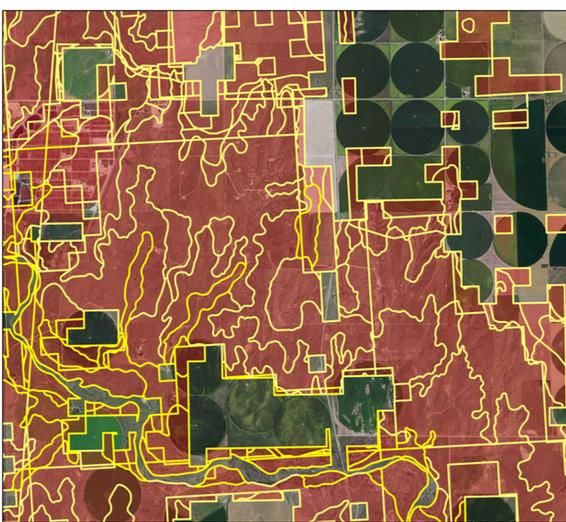

An aerial image of the research study area in southwestern Kansas.

Colorado State University

But corn is problematic as a biofuel source material. It's resource-intensive to grow, creates many environmental impacts, and is more useful as food.

A study from Colorado State University finds new promise for biofuels produced from switchgrass, a non-edible native grass that grows in many parts of North America. Scientists used modeling to simulate various growing scenarios, and found a climate footprint ranging from -11 to 10 grams of carbon dioxide per mega-joule -- the standard way of measuring greenhouse gas emissions.

To compare with other fuels, the impact of using gasoline results in 94 grams of carbon dioxide per mega-joule.

John Field, research scientist at the Natural Resource Ecology Lab at CSU, said what the team found is significant. "What we saw with switchgrass is that you're actually storing carbon in the soil," he said. "You're building up organic matter and sequestering carbon."

His CSU research team works on second-generation cellulosic biofuels made from non-edible plant material such as grasses. Cellulose is the stringy fiber of a plant. These grasses, including switchgrass, are potentially more productive as crops and can be grown with less of an environmental footprint than corn.

"They don't require a lot of fertilizer or irrigation," Field said. "Farmers don't have to plow up the field every year to plant new crops, and they're good for a decade or longer."

Researchers chose a study site in Kansas since it has a cellulosic biofuel production plant, one of only three in the United States.

The team used DayCent, an ecosystem modeling tool that tracks the carbon cycle, plant growth, and how growth responds to weather, climate and other factors at a local scale. It was developed at CSU in the mid-1990s. The tool allows scientists to predict whether crop production contributes to or helps combat climate change, and how feasible it is to produce certain crops in a given area.

Previous studies on cellulosic biofuels have focused on the engineering details of the supply chain. These details have included analyzing the distance between the farms where the plant material is produced, and the biofuel production plant to which it must be transported. However, the CSU analysis finds that the details of where and how you grow the plant material is just as significant or even more significant for the greenhouse gas footprint of the biofuel, said Field.

The biofuel industry is experiencing challenges, due to low oil prices. The production plant referenced above has new owners and is undergoing a reorganization.

But the future looks bright for biofuels and bioenergy, said Field.

"Biofuels have some capabilities that other renewable energy sources like wind and solar power just don't have," said Field. "If and when the price of oil gets higher, we'll see continued interest and research in biofuels, including the construction of new facilities."

Original publication

Original publication

John L. Field, Samuel G. Evans, Ernie Marx, Mark Easter, Paul R. Adler, Thai Dinh, Bryan Willson & Keith Paustian; "High-resolution techno–ecological modelling of a bioenergy landscape to identify climate mitigation opportunities in cellulosic ethanol production"; Nature Energy; 2018

Topics

Organizations

Other news from the department science

These products might interest you

BRC - Berghof Reactor Controller by Berghof

BRC - complete package for data acquisition, storage and control of all process parameters

Touch controllers are easy to use and provide quick access to all important functions

Berghof Reaktortechnologie - Hoch- und Niederdruckreaktoren, Druckbehälter und metallfreie Reaktoren by Berghof

Safe high- and low-pressure systems for aggressive media

Corrosion-resistant reactors with PTFE lining - individually configurable

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.