Surface modification using accelerated electrons

Fast, gentle, precise, stable and durable

Surfaces must satisfy a wide range of requirements: they need to be decorative, and even contribute substantially to hygiene. They also play a large role in biomedicine.

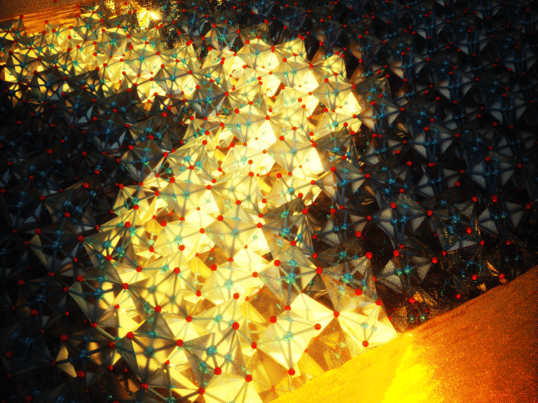

Wetting properties of functionalized surfaces with various liquids

© Fraunhofer FEP

There are numerous processes for functionalizing surfaces, depending on the application. Many are already well established and others are still under development by scientists throughout the world. Scientists at Fraunhofer FEP have already been working for a considerable time on functionalizing surfaces for the medical technology field. In addition to coating technologies, accelerated low-energy electrons are also employed for this purpose. The surface is selectively treated with these electrons in order to achieve suitable properties. Besides antibacterial effects, “self-cleaning” surfaces can also be created in this way.

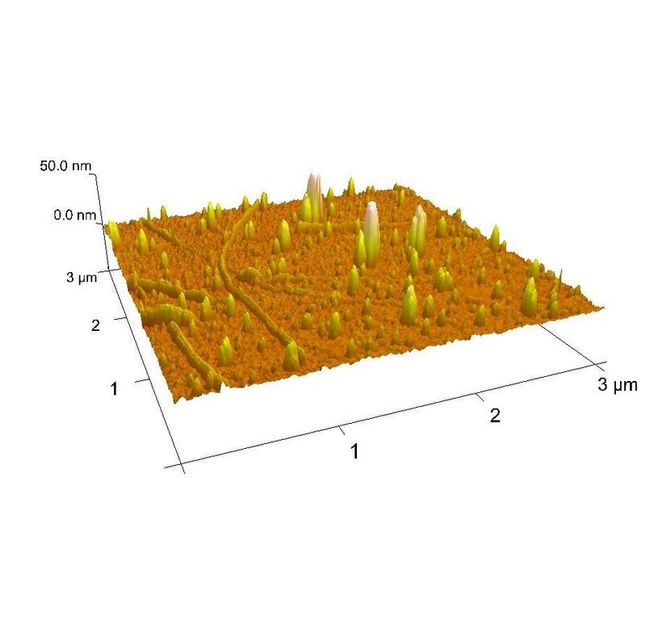

Electron beam treatment can result in a modification of the wetting characteristics for the surface (surface hydrophilicity), for example. In this way, the interaction of the surface with the environment can be selectively influenced. Human cells attach better, while bacteria in turn are rejected.

The order of magnitude of the dimensions for which this modification was able to be carried out is particularly noteworthy. Finely masking of samples with a lattice structure produced alternate hydrophilic (good wetting) and hydrophobic (poor wetting) surface areas with 100 μm separations. These very fine features characterized by differing surface energies are suited to lab-on-a-chip systems, for example, or for individualized growth patterns.

Gaby Gotzmann, head of hygienization, sterilization, and biofunctionalization at Fraunhofer FEP, explains: “While conventional processes often produce only temporary effects on surfaces, treatment with accelerated electrons leads to stable surfaces over a longer period. On suitable surfaces, the relevant areas can be treated very precisely, achieving penetration depths of even microns.”

Functionalization by means of electron beam was achieved rapidly. The challenge, however, lay in investigating the fundamental mechanisms of the effects in order to be able to reliably produce the results in the future. How the functionalization can be influenced by process parameters, needed to be explored. To accomplish this, comprehensive parametric studies were carried out by varying specific process parameters like atmosphere and incident energy, as well as in vitro cell tests that finally confirmed these insights.

The scientists are now able to set up a precise surface treatment procedure using electron beams for numerous surface applications in medical engineering and are seeking industrial partners for jointly producing functionalized surfaces.

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP will be presenting research results from the field of biofunctionalization and hygienization at the 13th ThGOT Thementage Grenz- and Oberflächentechnik in Zeulenroda, Germany, March 13 – 15, 2018.

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

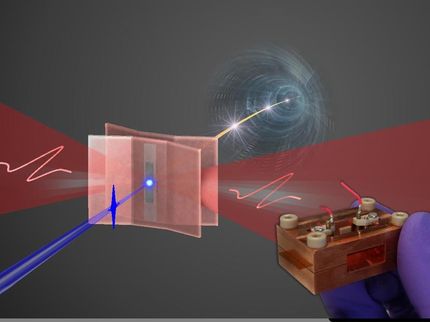

Tracking Tiny Particles

A predilection for certain symmetries: Researchers discover why atoms in solids show a preference for certain structures

Carbon_capture_and_storage

Fuel_cell

Retention_basin

An UV detector based on nanocrystals synthesized by using ion implantation

Borate

Umklapp_scattering

Gans_theory

Fetal_Alcohol_Spectrum_Disorder

Paper strips can quickly detect toxin in drinking water