New catalyst for hydrogen production is a step toward clean fuel

Advertisement

A nanostructured composite material developed at UC Santa Cruz has shown impressive performance as a catalyst for the electrochemical splitting of water to produce hydrogen. An efficient, low-cost catalyst is essential for realizing the promise of hydrogen as a clean, environmentally friendly fuel.

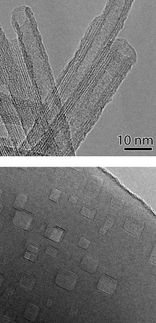

Researchers led by Shaowei Chen, professor of chemistry and biochemistry at UC Santa Cruz, have been investigating the use of carbon-based nanostructured materials as catalysts for the reaction that generates hydrogen from water. In one recent study, they obtained good results by incorporating ruthenium ions into a sheet-like nanostructure composed of carbon nitride. Performance was further improved by combining the ruthenium-doped carbon nitride with graphene, a sheet-like form of carbon, to form a layered composite.

"The bonding chemistry of ruthenium with nitrogen in these nanostructured materials plays a key role in the high catalytic performance," Chen said. "We also showed that the stability of the catalyst is very good."

Hydrogen has long been attractive as a clean and renewable fuel. A hydrogen fuel cell powering an electric vehicle, for example, emits only water vapor. Currently, however, hydrogen production still depends heavily on fossil fuels (mostly using steam to extract it from natural gas). Finding a low-cost, efficient way to extract hydrogen from water through electrolysis would be a major breakthrough. Electricity from renewable sources such as solar and wind power, which can be intermittent and unreliable, could then be easily stored and distributed as hydrogen fuel.

Currently, the most efficient catalysts for the electrochemical reaction that generates hydrogen from water are based on platinum, which is scarce and expensive. Carbon-based materials have shown promise, but their performance has not come close to that of platinum-based catalysts.

In the new composite material developed by Chen's lab, the ruthenium ions embedded in the carbon nitride nanosheets change the distribution of electrons in the matrix, creating more active sites for the binding of protons to generate hydrogen. Adding graphene to the structure further enhances the redistribution of electrons.

"The graphene forms a sandwich structure with the carbon nitride nanosheets and results in further redistribution of electrons. This gives us greater proton reduction efficiencies," Chen said.

The electrocatalytic performance of the composite was comparable to that of commercial platinum catalysts, the authors reported. Chen noted, however, that researchers still have a long way to go to achieve cheap and efficient hydrogen production.