Efficient Joining of Plastics With Infrared

Kleinostheim, 15 June 2002. Contact-less infrared heat joins plastic components without additional materials. Heraeus Noblelight, a company within the worldwide, precious metals and technology organization Heraeus Holdings GmbH, is showing infrared emitters, which help to facilitate the welding or fastening of plastic components, at the Fakuma Exhibition, in Friedrichshafen. The tailor-made emitters offer the advantage of allowing targeted heat to be applied: heat exactly where it is required and for only as long as it is needed by the process. Consequently, energy is used efficiently, process times are cut and, finally, production costs are reduced.

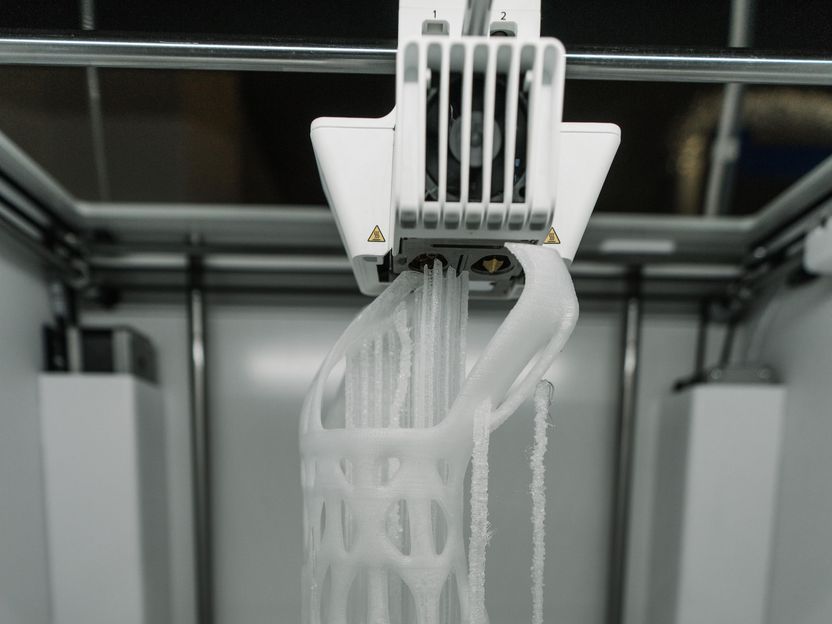

Plastic components are often produced in many parts and then joined together to form the finished item. Infrared heat helps to join tubes, to weld storage containers and to fasten interior cladding in motor vehicles. In comparison with conventional methods, many of these production steps are significantly simplified and speeded up using infrared radiation.

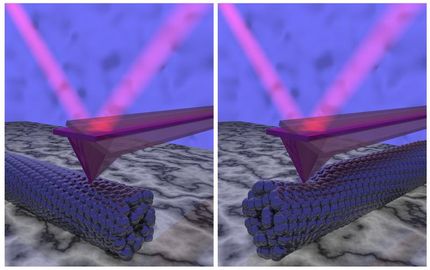

Infrared radiation heats plastic components without contact and, hence, cleanly. They can be joined without the need for additional adhesives or other materials. The infrared very rapidly melts a thin surface layer of the plastic parts, which can then be joined simply by pressing them together. Welding with infrared radiation takes place without the generation of noise or odors. In comparison with hot plate welding, no material sticks to the heat source and the heating process takes place in seconds and is reproducible every time.

Infrared emitters are matched exactly to the process step. They can heat large surfaces just as well as thin edges. Flexible designs also allow matching with complex geometry work pieces and infrared emitters are switched on and off in seconds so that energy and production costs are saved. Plastic components are efficiently fastened together in a few seconds because heat is applied to precisely the right point within a given time.

Other news from the department research and development

These products might interest you

Laboratory Heating Plates by AHF analysentechnik

Laboratory heating plates made of graphite - acid-resistant & durable

Discover the advantages of metal-free heating plates for your ICP-MS analyses

OHAUS Laboratory equipment by Ohaus

Do More with OHAUS Laboratory Equipment

Do Not Limit Yourself to Just Measurement! Discover Ingenious Portfolio

Hot plate stirrers by Velp Scientifica

Hot plate stirrers for a great range of applications, from basic to cloud-controlled ones

A complete range that features new standards for safety, efficiency, and ease of use

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.