A new way forward for nanocomposite nanostructures

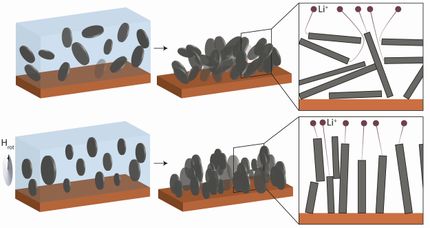

Scientists at the Naval Research Laboratory (NRL) and the University of Illinois — Urbana Champaign recently reported a new technique for directly writing composites of nanoparticles and polymers. Recent years have seen significant advances in the properties achieved by both these materials, and so researchers have begun to blend these materials into nanocomposites that access the properties of both materials. Forming these nanocomposites into structures has been tricky since each nanocomposite would require a particular set of solvents or a particular surface coating. To solve this problem, the NRL and UIUC team developed a generic means for depositing many nanocomposites on multiple surfaces with nanoscale precision. Metal nanoparticles that were conducting, tiny magnetic nanoparticles, and nanoparticles that glowed, were all deposited using this one technique.

The technique builds on previous work using atomic force microscopy (AFM) probes as pens to produce nanometer-scale patterns. The polymer-nanocomposite blend is coated onto the probe. When the probe is heated, it acts like a miniature soldering iron to deposit the nanocomposite. "This technique greatly simplifies nanocomposite deposition," said Paul E. Sheehan, head of the Surface Nanoscience and Sensor Technology Section at NRL in Washington, D.C. "No longer do you have to spend half a year tweaking the chemistry of the surface or nanocomposite to achieve deposition."

The technique also solves a common problem when depositing soft materials like polymers and nanocomposites. The solvents and patterning procedures for depositing soft materials can damage any soft material already deposited. Consequently, it can be quite difficult to deposit many different such materials. "Our ability to control nanometer-scale heat sources allows local thermal processing of these nanocomposites," says William King, Kritzer Faculty Scholar in the Department of Mechanical Science and Engineering at the University of Illinois Urbana-Champaign. This opens a door to the direct writing of highly complex structures.

Although the nanoparticles were typically dispersed throughout the nanocomposite, the researchers found that by adjusting the nanoparticle chemistry they could force the nanoparticles into alignment. "With the right chemistry, the forces in the polymer will guide the nanoparticles into thin rows." Rows of nanoparticles less than 10 nm wide were written, narrower than any other direct write technique. The string of magnetic nanoparticles should be useful for studying magnetic interactions on the smallest scales. "Combining with our nanolithographic technique these tiny magnetic nanostructures can be added to current electronic or MEMS devices to enhance their capabilities." says Woo Kyung Lee. "These capabilities and those of the other nanocomposites may find novel applications from microelectronics to biomedical devices."

Topics

Organizations

Other news from the department science

These products might interest you

MS-Präzisionswaagen by Mettler-Toledo

Trusted Results at Your Fingertips

Capacity from 320 g to 12.2 kg, readability from 1 mg to 100 mg

Good Weighing Practice by Mettler-Toledo

Your Concrete Weighing Quality Assurance Plan

GWP Verification service

Precision balances by Ohaus

High-performance precision balances for everyday use in laboratories & industry

From milligram-accurate measurement of small samples to routine weighing in the kilogram range

Automatische XPR-Waagen by Mettler-Toledo

Production of standards, samples and concentrations - fast and reliable

Automate the weighing processes in your laboratory - ideal also for sample prep at chromatography

XPR Precision Balances by Mettler-Toledo

Fast and Accurate Precision Weighing Even in Difficult Conditions

XPR Precision Balances / Solutions to support you with data management, traceability and regulatory compliance

Carepacs by Mettler-Toledo

Professional CarePacs for smooth routine testing

Tweezers, gloves and other accessories for professional weight handling

Balances analytiques by Ohaus

Analytical balances with outstanding weighing performance, as easy to use as a smartphone

These space-saving analytical and semi-micro balances are surprisingly intuitive to use

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

TROXATYLTM PHASE I LEUKEMIA DATA PUBLISHED TODAY IN JOURNAL OF CLINICAL ONCOLOGY

Papain