Ozone detection

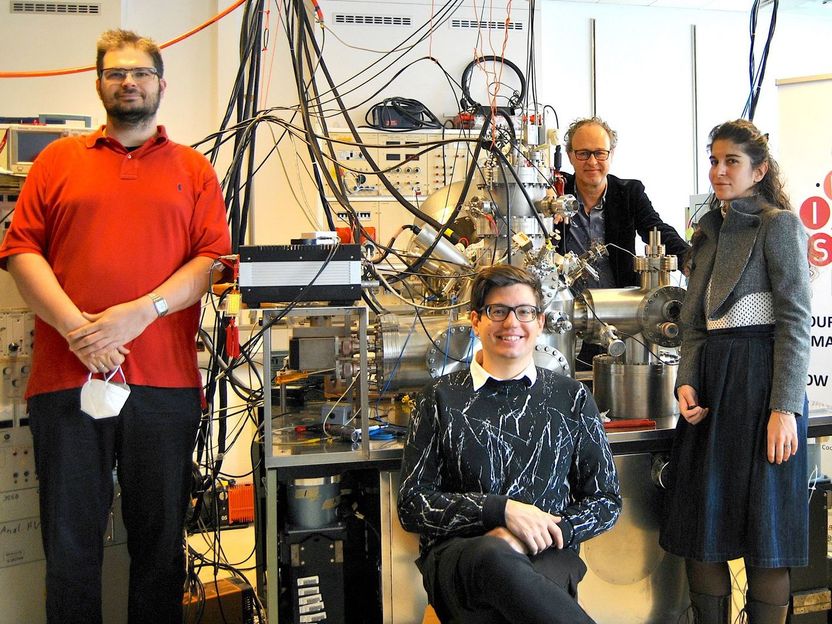

Researchers in Freiburg have developed a highly-sensitive, miniaturized mobile ozone sensor which can be used not only in air, but also in water and in the vicinity of explosive gases.

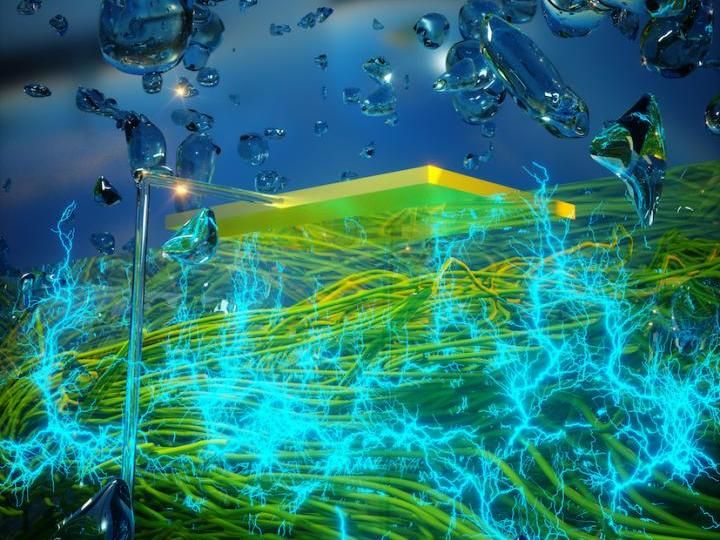

The Fraunhofer Institute for Applied Solid State Physics IAF in Freiburg is developing improved chemical sensors that are not prohibitively expensive. One particularly important area of application involves the regular measurement of ozone content in air and other media. This gas is a powerful oxidizing agent and can cause a wide range of symptoms in humans, including lacrimation, irritation of the mucous membranes in the mouth, throat, and bronchial tubes, headaches, coughing and even deterioration in lung function. The main sources of ozone pollution are industrial and transport emissions; particularly in warmer weather, these react with intensive UV radiation to form ground-level ozone. But laser printers and copiers, machines so prevalent in modern-day offices, can also emit ozone. The European Commission has announced its intention to cut the guideline value for ozone in the air from the current level of 90 parts per billion to 60 parts per billion by 2010, and when this new regulation comes into force, there will be an increased demand for inexpensive ozone sensors. But as project manager Dr. Volker Cimalla of the IAF explains: “Since ozone is, at the same time, an agent with high application potential, novel sensors are required, which have to be compact and affordable.” Sensors are essential equipment in industrial settings such as wastewater treatment facilities and water sterilization units, where they are used to monitor the ozone concentration – firstly to ensure the required concentration for the relevant application is maintained, and secondly to guard against exceeding hazardous thresholds for humans.

Project manager Cimalla says: “The ozone sensors currently available on the market employ extremely laborious and complex measuring procedures such as UV absorption and are therefore very expensive. By contrast, the more affordable ozone sensors have to be heated up to 300 degrees Celsius and produce inaccurate readings or only work in limited areas of application. We’ve done away with the need for heating by instead applying blue/violet light radiation to trigger the chemical process necessary for regeneration on the sensor surface – this allows the sensors to operate at room temperature.” The scientists built on the existing knowledge that molecules absorbed on the surface of a sensing layer alter its electrical resistance – and can also be removed again by light irradiation. The result is a highly-sensitive, miniaturized sensor capable of measuring the low ozone levels that occur in environmental and ambient air monitoring just as accurately as the high levels associated with industrial process control. And since the sensor is extremely small, it can even be integrated into mobile equipment.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.