Scientists' breakthrough in production of biofuels

A team of scientists from the University of Sheffield have scooped an international award in recognition of their work on an innovative device which will make the production of alternative biofuels more energy efficient.

The research team has adapted a unique bioreactor for use in the production of alternative renewable fuels, to replace fossil fuels such as petrol and diesel. The manufacture of biofuels currently requires vast amounts of power and when the process uses too much energy, it is uneconomic. This new method consumes much less energy and could prove to be vital to the economic, green production of alternative fuels.

The team have devised an air-lift loop bioreactor which creates microbubbles using 18% less energy consumption. Microbubbles are miniature gas bubbles of less than 50 microns diameter in water. They are able to transfer materials in a bioreactor much more rapidly than larger bubbles produced by conventional bubble generation techniques and they consume much less energy. The team's unique adaption of the bioreactor and creation of microbubbles has the potential to revolutionise the energy-efficient production of biofuels.

In recognition of this breakthrough, the team have been awarded the Moulton Medal from the Institution of Chemical Engineers, which recognises the best paper published in the Institution's journal during the year. The team also submitted their project as a poster to the 6th Annual bioProcessUK conference, where it picked up the Best Poster Award.

The approach is currently being tested with researchers from Suprafilt in Rochdale on industrial stack gases. The team are also currently testing the application of the device with local water company Yorkshire Water. They are using the components of the bioreactor that produce microbubbles to give a better performance in the treatment of wastewater. They are predicting to reduce the current electricity costs for this process by a third.

Professor Will Zimmerman, from the Department of Chemical and Process Engineering at the University of Sheffield, said: "I am delighted that our team's work in energy efficient microbubble generation is being recognized by the Institution of Chemical Engineers. The potential for large energy savings with our microbubble generation approach is huge. I hope the award draws more industry attention to our work, particularly in commodity chemicals production for gas dissolution and stripping, where energy savings could enhance profitability. There are many routes to becoming green, and reducing energy consumption with the same or better performance must be the most painless."

Professor Martin Tillotson, from Yorkshire Water, added: "Many of our processes use forced air in order to treat water and wastewater streams and, given the huge volumes, it is very costly in electricity and carbon terms. This technology offers the potential to produce a step-change in energy performance. We are pleased to be working with Professor Zimmerman and his group in developing the microbubble technology, and delighted with the recognition they have received from the Moulton Medal award."

Topics

Organizations

Other news from the department science

These products might interest you

BRC - Berghof Reactor Controller by Berghof

BRC - complete package for data acquisition, storage and control of all process parameters

Touch controllers are easy to use and provide quick access to all important functions

Berghof Reaktortechnologie - Hoch- und Niederdruckreaktoren, Druckbehälter und metallfreie Reaktoren by Berghof

Safe high- and low-pressure systems for aggressive media

Corrosion-resistant reactors with PTFE lining - individually configurable

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Henkel heading for further profitable growth with adhesives

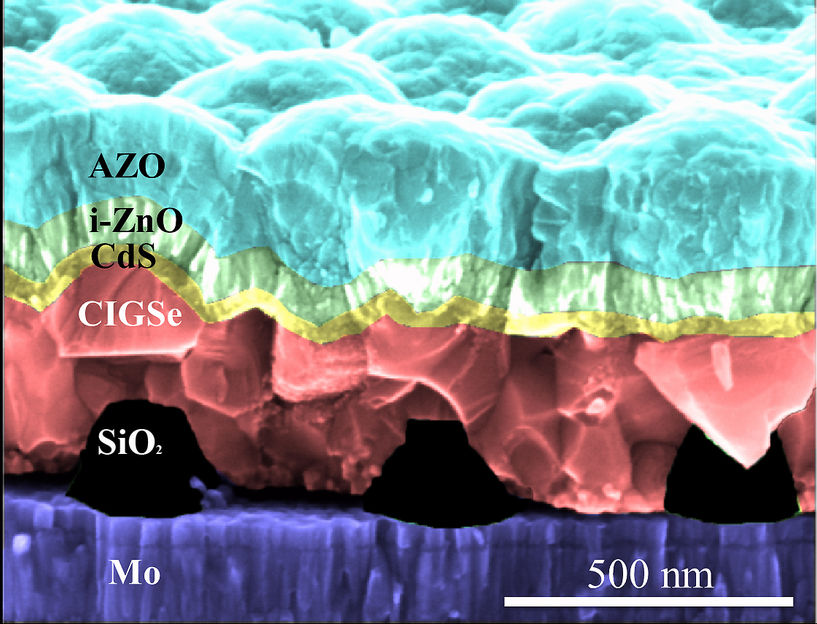

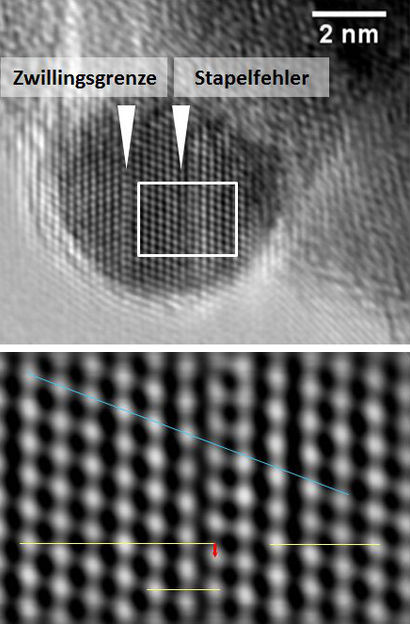

Defects make catalysts perfect - Insights into the process which converts carbon dioxide into methanol could make it possible to recycle greenhouse gas

Class_III_β-tubulin

Clariant divests its Pigments business - Closing anticipated in the first half of 2022

Remington_medal

NEMO Project: 11 Partners Conduct Research on New OLED Materials - German Federal Ministry of Education and Research (BMBF) is supporting the research project “New materials for OLEDs from solutions” (NEMO)