Safe journey for works of art

Valuable paintings travel long distances when they are shipped from one place to another. To minimize damage, they are packed in special picture cases. In future, these will be equipped with sensors to detect the buildup of pollutant gases, emanating from adhesives for example.

After being exhibited in New York, the priceless oil paintings move on to a gallery in Paris and then to a museum in Berlin. To protect the works of art from the effects of the environment during transport and storage, they are packed in special cases made of plastic, wood and glass. The microclimate inside these cases keeps the polluted outside atmosphere at bay. But the works of art are still exposed to a certain amount of risk, because the wood, plastics and adhesives used to make the transport containers can also emit damaging substances such as acetic acid. These substances react with the oil paint, causing it to gradually degrade. The painting itself can also emit pollutant gases that build up inside the case. Similar problems can be encountered when paintings are stored in the vaults of a museum or put on display in an enclosed, climate-controlled showcase.

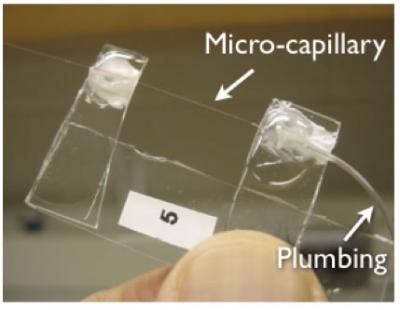

In future, various types of environmental sensors will be available to measure the rising concentration of gases inside the case. They have been developed by researchers at the Fraunhofer Institute for Silicate Research ISC in Würzburg in collaboration with a number of European project partners. One of these sensors is a glass dosimeter, which is particularly sensitive to the presence of acids. As the head of the relevant ISC business unit Dr. Gerhard Schottner explains: “The acid attacks the surface of the glass and gradually erodes it. After a few days, a reaction layer starts to form. We quantitatively analyze this reaction layer using an infrared spectrometer. A few weeks later, crystalline products may also start to appear on the surface of the glass, enabling us to identify the type of acid involved.” Atmospheric pollutants have a similar effect, producing nitrogen and sulfuric oxides. The new sensors detect such aggressive compounds in the air inside the showcase.

“The sensors help us to identify the pollutant gases and determine which were produced inside the showcase and which have penetrated it from outside. They enable us to build zero-emission showcases and substantially improve the microclimate surrounding the valuable artworks,” says Schottner. The sensors are also useful when assessing claims for damages sustained by a painting during shipment, because they enable the display-case manufacturer to provide documented evidence of the origin of the harmful emissions. The research team has already conducted initial pilot tests.

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.