Ashland Foundry Products Division Invests in Quality Enhancement Upgrades

Dublin, Ohio (USA) – The Foundry Products Division of Ashland Specialty Chemical Company, a division of Ashland Inc., has begun a $1 million capital improvement project to install automated process controls and other upgrades for enhancing product quality at its Cleveland-East manufacturing plant. The facility manufactures a full line of refractory coatings and specialty chemicals for the foundry industry and isAshland’s leading producer for these products.

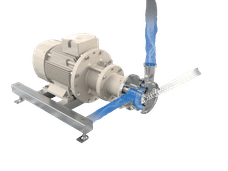

The first phase of the improvement project has now been completed with installation of a highly automated process monitoring and control system. This achieves precise ‘recipes’ by adding raw materials – known as ‘charging’ – to the processing mixers and controlling the mixing operations.

The system improves charging accuracy through accurate weighing and dispersion of the materials, and by ensuring that they are added at the proper rate. The computerized and user- friendly system also generates data for tracking the operations – valuable information that minimizes the need for batch adjustments and promotes first-time quality.

“Our customers' expectations on SQC and SPC for refractory coatings are becoming much more demanding as they themselves set more stringent quality expectations including, in some cases, Six Sigma programs,” said Michael W. Swartzlander, vice president and general manager, Foundry Products Division, Ashland Specialty Chemical Company. “Ashland has a long history of developing and introducing higher quality to refractory coatings; for example, leading the industry conversion from pastes that required mixing at the foundry, to ready-to-use slurries. Adding these state-of-the art capabilities to our manufacturing processes is a natural extension of our commitment to making refractory coatings more predictable and useful in the foundry," Swartzlander said.

The Foundry Products Division manufactures and sells foundry chemicals worldwide, including sand-binding resins systems, refractory coatings, release agents, engineered sand additives and riser sleeves. It serves the global metal casting industry from 38 manufacturing and distribution locations. For more information, contact Ashland Foundry Products Division at 614-790-3514 or visit the web site at www.ashspec.com/fp.html.

Topics

Organizations

Other news from the department science

These products might interest you

2mag Magnetic Stirrers Catalogue 2024 by 2mag

Wear-free magnetic stirrers for laboratory and cell culture

Request the 2mag catalogue 2024 with innovative stirring solutions now

THINKY ARE-250 by C3 Prozess- und Analysentechnik

Perfect mixing and effective degassing in record time - Discover the revolutionary solution for your mixing and degassing needs

THINKY ARE-500 by C3 Prozess- und Analysentechnik

Efficient mixing and degassing in minutes - The revolutionary mixer and disperser without stirrer

Impulsmischer by Hybrid Chemie

Pneumatic mixer for homogenizing solutions, suspensions and emulsions

Gentle, efficient mixing, regardless of the fill level, even for high viscosities

Mini Vortex Mixers by Ohaus

Your vortex mixer for perfect mixing in any application

Your durable laboratory assistant for everyday mixing and vortexing

OHAUS Laboratory equipment by Ohaus

Do More with OHAUS Laboratory Equipment

Do Not Limit Yourself to Just Measurement! Discover Ingenious Portfolio

YSTRAL Conti-TDS by ystral

YSTRAL Conti-TDS: The No. 1 in Powder Wetting

Induct, wet and disperse powder

MultiDrive by IKA Werke

The Universal Crusher: Weigh and Crush Using the Same Mixing Cup!

Mix, grind, disperse – no matter whether your samples are hard, soft or fibrous

Innovative Magnetic Stirrers by 2mag

Magnetic stirrer of the future - for laboratories and pilot plants

Individually configurable, 100 % wear-free, 3-year guarantee

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.