Improved competitiveness through process intensification for the chemical industry

EU project COPIRIDE under coordination of IMM begins

Advertisement

The project COPIRIDE, partly funded by the EU Seventh framework programme for research and technological development, started. This project develops new technologies, processes and manufacturing concepts for the “plant of the future”. Thereby, not only an improvement of the efficiency and sustainability but also an increase in innovative ability and competitiveness within the chemical industry in Europe shall be achieved.

The Institut fuer Mikrotechnik Mainz (IMM) will coordinate the project with a duration of 3.5 years under the supervision of IMM’s R&D director Prof. Dr. Volker Hessel. 15 further European companies and academic partners participate in the project COPIRIDE which is funded by the European Commission with a total of 11 million Euros.

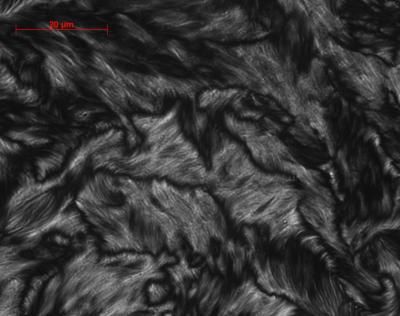

Due to emerging markets and high production capacity e.g. in Asia the chemical industry in Europe suffers from considerable cost and environmental constraints. A promising approach to meet the competitive pressure arises from process intensification where - in contrast to process optimization enhancing existing processes - totally new concepts for process steps and equipment are developed, in particular by means of micro structured reactors. The latter are turning the two main adjustment screws of chemical and economical efficiency: more effective use of resources by a better selectivity towards the product and utilization of process windows with orders of magnitude faster chemical conversions.

COPIRIDE takes the approach of developing a multifunctional and all-purpose plant platform. Multiple plants and reactors are integrated in compact format e.g. a container to be applicable for different processes with a very high flexibility. The project members expect a maximization of productivity by minimizing the setup time, improved sustainability, lower capital costs, higher process security and energy efficiency as well as a direct economical benefit within the range of approximately 10 to 30 million Euros per year. “Due to the technology transfer an indirect economical benefit of approximately 800 million Euros is possible.” says Prof. Dr. Volker Hessel. Another focus is the standardisation and further development of micro structured reactors for mass production as these so far could only be used in laboratory and pilot plants.

The main aspect is a strong interdisciplinary pooling of knowledge. Through the project know-how of the market leaders and major companies in the area of micro process technology is made accessible and transferred even across sectors to European small and medium-sized companies (SME) which had little contact with micro process technology so far. The concept will be demonstrated by 5 industrially significant model applications in European SMEs of diverse sectors. The range of applications comprises the areas food ingredients, bio fuels, biomass conversion and specialty chemistry. Europe’s fourth biggest chemical market Italy will serve as first test area.