Wacker and Dow Corning Start to Build Second Phase of Pyrogenic Silica Plant in Zhangjiang, China

Wacker Chemie AG and Dow Corning Corporation officially started the construction of the second phase of their pyrogenic silica plant in Zhangjiagang, Jiangsu province, China. The pyrogenic silica plant, together with a siloxane plant, is a key facility of an integrated silicone manufacturing site developed by both companies at Jiangsu Yangtze River Chemical Industrial Park in Zhangjiagang to produce materials used extensively in industries including construction, beauty and personal care, power and automotives.

The overall nameplate capacity for both siloxane and pyrogenic silica, including the second phase silica plant , is expected to be approximately 210,000 metric tons per year. Investments from both partners for the new pyrogenic silica production plant will amount to a mid double-digit million euro sum.

Pyrogenic silica is a nano-structured specialty chemical. It can be used as an active filler in silicone elastomers, a viscosity-adjusting agent in coatings, printing inks, adhesives, unsaturated polyester resins and plastisols or as a flow aid, for example in the cosmetics, pharmaceutical and food-processing industries.

Both companies also own and manufacturing plants for finished silicone products at the Zhangjiagang site. Marketing and sales are undertaken independently by each company.

Other news from the department manufacturing

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

AMSilk and Fraunhofer Institute for Applied Polymer Research Join in the Development of New Spin Process for Spider Silk

Stress_corrosion_cracking

Hydrofluoric_acid

Next generation of biodegradable plastic introduced by eastman

Alcoa Receives Hart-Scott-Rodino Request for Additional Information in Connection with Outstanding Offer for Alcan

Heegaard_splitting

EPSRC unveils world-leading SuperSTEM microscope that sees single atoms

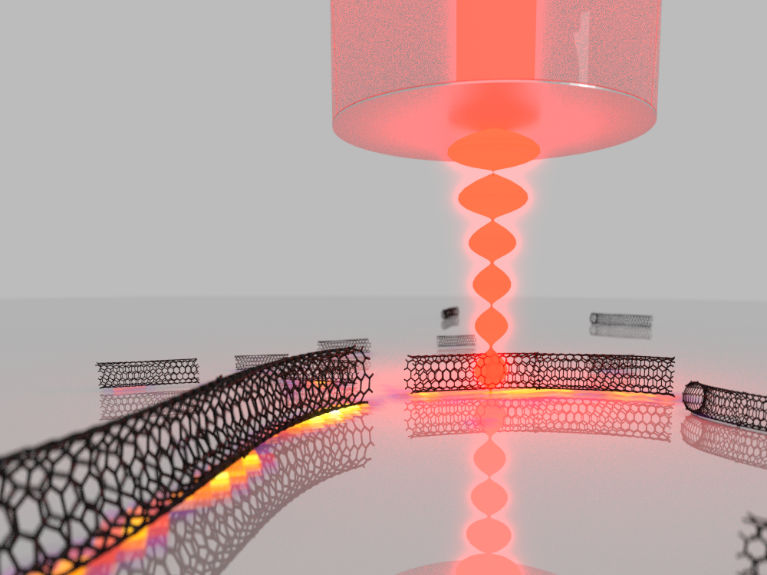

A signal boost for molecular microscopy - Cavity-enhanced Raman-scattering reveals information on structure and properties of carbon nanotubes

Bentiromide

Haplogroup_I1a_(Y-DNA)