Getting to the roots of lethal hairs

Fine metal hairs, also called metal whiskers, on tin-plated copper cause short circuits in electronic components. An international team of researchers is finding out why they grow

A short circuit can be quite hairy: satellites have failed, a NASA computer centre was repeatedly paralysed and the US public heath authority recalled thousands of pacemakers - all because tin whiskers caused a short circuit in the electronic components of these devices. A team of scientists from the Max Planck Institute for metals Research has been working with Robert Bosch GmbH to measure the forces that trigger this metallic hair growth. Tin whiskers can be up to a few millimetres long and just a few micrometres in diameter. They sprout from the tin used to solder and plate electronic components made of copper. Understanding in detail what makes the whiskers grow is the first step on the way to preventing their growth.

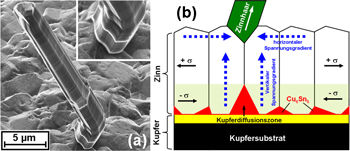

(a) This image from an ion beam microscope shows the growth morphology of a tin whisker. (b) A model of the forces that cause spontaneous whisker growth on tin-plated copper. The tin coating is a few micrometres thick.

Max Planck Institute for Metals Research, Stuttgart

The systems in a NASA computer centre failed after new data storage had been installed; at least 18 short circuits occurred in the high-performance computers before technicians found the reason: the replacement of the storage devices dislodged metal whiskers from the base construction and their subsequent distribution via air circulation caused system failure by bridging the electrical circuits of the supercomputers.

Researchers working with Eric J. Mittemeijer at the Max Planck Institute for Metals Research together with colleagues from the Robert Bosch GmbH, Argonne National Laboratory in Illinois and Oak Ridge National Laboratory in Tennessee have revealed the forces that cause these whiskers to sprout from tin-plated copper. According to their findings, the pressure of the tin atoms at the base of the film needs to be higher than at the surface. At the same time, there must be a pressure difference on the film’s surface plane: The pressure at the root of the tin whisker must be lower than it is further away. "You can compare it to a toothpaste tube," says Matthias Sobiech, who carried out the experiments. "When you press the sides, toothpaste comes out of the top." The pressure, which physicists also call stress, is created because an intermetallic tin-copper compound forms at the tin-copper interface that grows further into the tin film.

X-ray investigations provided a detailed picture of the distribution of the stress in the tin film. The researchers determined the stress differences between the base and the surface of the tin film in their laboratory in Stuttgart by measuring step by step the vertical mechanical stresses. In order to measure the distribution of stress in the surface plane around a growing whisker, the researchers had to use a method with very high spatial resolution in the sub-micron range. These micro stress measurements were taken using the synchrotron at the Advanced Photon Source at Argonne National Laboratory by means of the Micro Laue Diffraction method: A very fine beam of X-rays, around 300 nanometres in diameter, scanned the surroundings of a growing tin whisker in very small steps, and a sensitive detector very precisely recorded the local stresses at each probed position.

"We showed, for the first time, that tin whiskers are formed on tin layers which clearly exhibit mechanical stress differences," says Eric J. Mittemeijer, Director at the Max Planck Institute for Metals Research in Stuttgart. "And that these stress differences are the driving force for the growth of the whiskers." He and his colleagues demonstrated this in experiments by measuring local stress distributions in films that exhibit whisker growth and in films that do not exhibit whisker growth.

Looking closely at the state of stress in a material can be helpful in many investigations. It reveals a lot about the forces that operate in electronic or mechanical microsystems, which might have a detrimental effect on their function - in the same way as the tin whiskers cause short circuits in electronic components. "We hope that our findings will help to protect electronic components from the growth of tin whiskers," says Matthias Sobiech. "Because we now know that it is important to remove the stress differences in the film." The researchers are now setting out to investigate how that can be done successfully.

Original publication: Matthias Sobiech et al.; "Local, submicron, strain gradients as the cause of Sn whisker growth"; Applied Physics Letters 94 (2009), 221901

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.