Irregularities in catalyst inhibit crude oil conversion

Blueprint of the catalyst's interior

Advertisement

Irregularities in industrial catalysts can inhibit the conversion of crude oil, Utrecht University chemists have concluded. They were the first to provide a detailed blueprint of the interior of a commercially used catalyst for e.g. the production of transportation fuels from crude oil. They discovered a large number of dead ends. Their findings can contribute to the development of new and improved catalytic materials for the chemical industry. The study has been published in Nature Materials.

In collaboration with various international research groups, Professor Bert Weckhuysen and PhD students Lukasz Karwacki and Marianne Kox of Utrecht University have studied the internal architecture of zeolite materials in great detail. These catalysts can be compared to Swiss cheeses, containing molecular-sized holes and channels. Zeolites play a crucial role as catalyst materials in the (petro-) chemical industry to convert crude oil into transportation fuels, such as kerosene, diesel and gasoline. In this process, which is called catalytic cracking, crude oil is forced through the Swiss cheese ‘channels’ where it is split into smaller fractions. In this way, long crude oil molecules are cut up, for example, into gasoline molecules. However, the researchers discovered that not all of the zeolite channels are equally accessible.

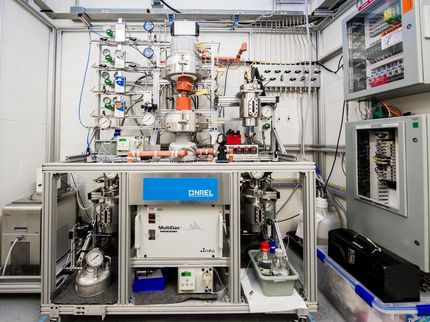

Using a combination of various advanced microscopic techniques, the researchers created a blueprint of the catalyst showing that the materials contain a regular pattern of different channel obstructions. They found for example that a large number of zeolite channels are not open-ended. This disruption of the channel layout means the catalyst does not function optimally. ‘The molecules reach ‘dead ends’ in the zeolite crystal and the only option is to turn back,’ says Professor Bert Weckhuysen. ‘But that’s not possible, because there’s already a queue of molecules behind them. From a practical point of view, this means that the advantages of zeolite catalysts are only partially exploited.’

Original publication: “Morphology-dependent MFI-type zeolite intergrowth structures leading to distinct internal and outer-surface molecular-diffusion barriers”, Nature Materials 2009.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.