Friction force differences could offer a new means for sorting and assembling nanotubes

Advertisement

nanotubes and nanowires are promising building blocks for future integrated nanoelectronic and photonic circuits, nanosensors, interconnects and electro-mechanical nanodevices. But some fundamental issues remain to be resolved – among them, how to position and manipulate the tiny tubes.

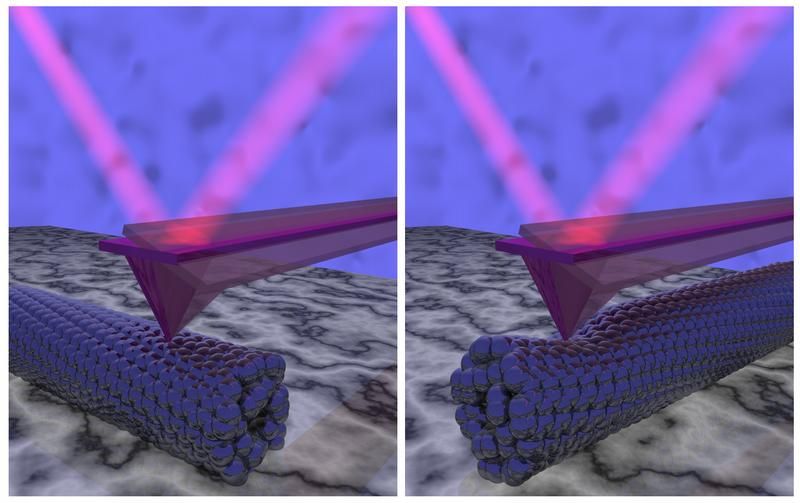

These images compare an AFM tip sliding longitudinally along a carbon nanotube (left) versus sliding in the transverse direction.

Universität Hamburg

Publishing in the journal Nature Materials, researchers from four different institutions report measuring different friction forces when a carbon nanotube slides along its axis compared to when it slides perpendicular to its axis. This friction difference has its origins in soft lateral distortion of the tubes when they slide in the transverse direction.

The findings not only could provide a better understanding of fundamental friction issues, but from a more practical standpoint, offer a new tool for assembling nanotubes into devices and clarify the forces acting on them. Asymmetries in the friction could potentially also be used in sorting nanotubes according to their chirality, a property that is now difficult to measure with other means.

When an atomic force microscope (AFM) tip is scanned transversely across a multi-walled carbon nanotube, the amount of friction measured is twice as much as when the same tube is scanned longitudinally, along the length of the tube. The researchers attribute this difference to what they call "hindered rolling" – additional effort required to overcome the nanotube's tendency to roll as the AFM tip strokes across it rather than along it.

"Because the energy required to move in one direction is twice as much as required to move in the other direction, this could be an easy way to control the assembly of carbon nanotubes for nanoelectronics, sensors and other applications," said Elisa Riedo, co-author of the study and an associate professor in the School of Physics at the Georgia Institute of Technology. "To assemble nanotubes on a surface, you need to know how they interact and what force is needed to move them."

The combined theoretical and experimental study was supported by the U.S. Department of Energy. Other institutions contributing to the project include the International Centre for Theoretical Physics, International School for Advanced Studies and CNR Democritos Laboratory – all in Trieste, Italy – and the University of Hamburg in Germany. The paper was published in advance online on September 13 by the journal Nature Materials.

Carbon nanotubes have exceptional thermal, mechanical and electrical properties that have generated considerable interest since they were first reported in 1991. Though friction has been studied before in nanotubes, this research is the first to provide detailed information about the frictional forces at work in both the longitudinal and transverse directions when the tubes interact with an AFM tip.

Friction is one of the oldest problems in physics and one of the most important to everyday life. It is estimated that the losses in the U.S. economy due to friction total about 6 percent of the gross national product. Friction is even more important to micro-electromechanical systems (MEMS) and nanoscale devices because these smaller systems are more affected by surface forces than large systems.

"As systems become smaller and smaller, it becomes more important to understand how to address friction," said Riedo. "Surface forces can prevent micro and nano systems from operating at all."

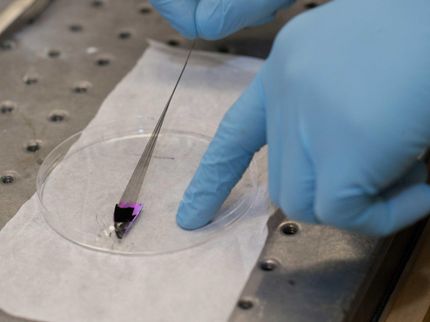

Experimentally, the researchers scanned an atomic force microscope tip longitudinally along a series of multiwalled carbon nanotubes held stationary on a substrate. They also conducted a series of similar scans in the transverse direction. The researchers applied a consistent force on the AFM tip in both scanning directions, and relied on powerful Van der Waals forces to hold tubes in place on the substrate.

"When you scan a nanotube transversely, you are probing something very different," said Riedo. "You are also probing additional dissipation modes due to a kind of swaying motion in which energy is also dissipated through movement of the nanotube as it alters its cross section."

The experiment showed that greater forces were required to move the tip in the transverse direction. Using molecular dynamics simulations, collaborators Erio Tosatti and Xiaohua Zhang at the International Centre for Theoretical Physics, International School for Advanced Studies and CNR Democritos Laboratory analyzed the phenomenon to understand what was happening.

"In principle, there seems to be no reason why the frictional forces required to move the AFM tip would be different in one direction," Riedo noted. "But the theory confirmed that this 'hindered rolling' and soft mode movement of the nanotubes are the sources of the higher friction when the tip moves transversely."

Because the nanotube-tip system is so simple, it offers an ideal platform for studying basic friction principles, which are important to all moving systems.

"This kind of system gives you the opportunity to explore friction using an ideal experiment so you can really probe the energy dissipation mechanism," Riedo explained. "The system is so simple that you can distinguish between the dissipation mechanisms, which you can't usually do well in macro-scale systems."

Based on the molecular dynamics simulations, Riedo and Tosatti believe that the friction anisotropy will be very different in chiral nanotubes versus non-chiral – left-to-right symmetric – nanotubes.

"Because of the chirality, the tip moves in a screw-like fashion, creating hindered rolling even for longitudinal sliding," Tosatti said. "Thus, the new measuring technique may suggest a simple way to sort the nanotubes; among the next steps in the research will be to show experimentally that this can be done."

In addition to the researchers already mentioned, co-authors for this paper include Christian Klinke at the Institute of Physical Chemistry at the University of Hamburg, and Marcel Lucas and Ismael Palaci at Georgia Tech.

"Understanding the basic mechanism of friction in carbon nanotubes will help us in designing devices with them in the future," Riedo added. "We have shown an anisotropy in the friction coefficient of carbon nanotubes in the transverse and longitudinal directions, which has its origin in the soft lateral distortion of tubes when the tip-tube contact is moving in the transverse direction. Our findings could help in developing better strategies for chirality sorting, large-scale self-assembling of nanotubes on surfaces, and designing nanotube adhesives and nanotube-polymer composite materials."

Other news from the department science

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.