SCG-DOW Group Commemorates Thailand HPPO Progress with Stone Laying Ceremony

PO facility at Map Ta Phut on schedule to start up in 2011

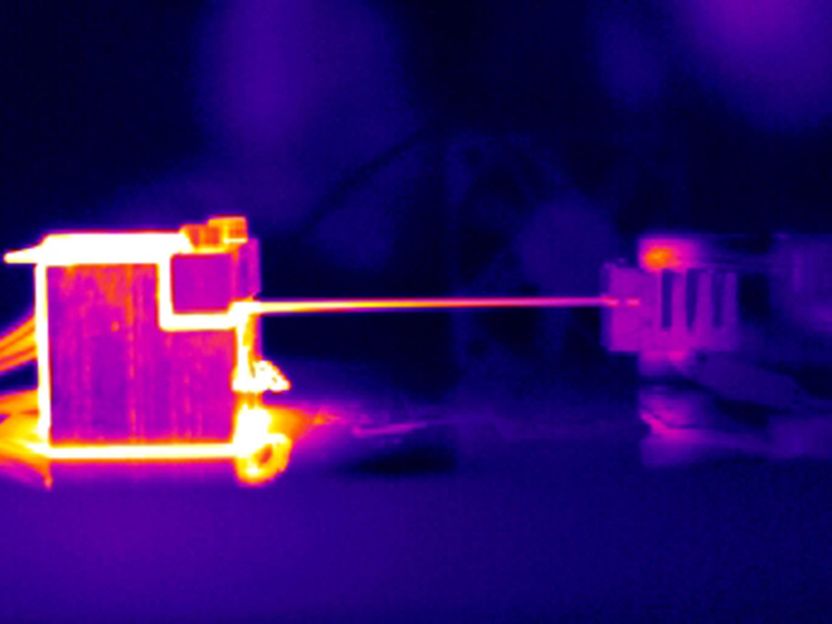

The Dow Chemical Company (Dow) announced that the SCG-DOW Group, a joint venture between Dow and The Siam Cement Group (SCG), and Solvay Peroxythai Ltd. recently commemorated significant milestones on the hydrogen peroxide to propylene oxide (HPPO) related investments with a foundation stone laying ceremony at the Asia Industrial Estate (AIE) site near Map Ta Phut, Thailand, where the HPPO facility is being built.

The SCG-DOW Group has procured all equipment and entered the initial construction phase on a world-scale propylene oxide (PO) plant, with an anticipated start-up in the first half of 2011. Once complete, the facility will manufacture PO via HPPO technology jointly developed by Dow and BASF, and will have a name plate capacity of 390 kilotons per annum (KTA).

The AIE site will also feature a specialty elastomers plant; a hydrogen peroxide plant built as a joint venture between Dow and Solvay; and power utilities and infrastructure. Nearby, a new liquids cracker, also jointly owned by SCG and Dow, will come on stream in 2010. The integrated Thailand plants represent a significant increase of the asset base for Dow in Thailand and Dow’s largest manufacturing investments in Asia Pacific.

“This significant strategic investment helps enable Dow Polyurethanes to leverage our low cost-to-serve leadership position across the portfolio as well as fuel the growth of Dow’s other Performance and Advanced Materials businesses,” said Pat Dawson, president of Dow Polyurethanes, a global business group of Dow. “The new large-scale, back-integrated plant, based on advanced HPPO technology, will be best positioned to address the region’s increasing demand for PO and derivatives, which are driven by increased demand in markets such as appliance, construction, coatings, adhesives and sealants. Our customers in Asia Pacific will benefit from the reliable supply of this key raw material they need to competitively grow their business. Dow and our joint venture partners are very pleased to be able to offer the PO technology that delivers greater energy efficiency, a reduced physical footprint, and improved environmental performance.”

Other news from the department manufacturing

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Plastics in electrical waste: Disposal or recycling?

The Linde Group to invest in largest air separation plant in India - EUR 85 million investment is part of a long-term gas supply contract with Tata Steel

Chromatin and Pacific Ethanol sign agreement for locally-grown sorghum in ethanol production

AkzoNobel announces intention to restructure and split ICI Pakistan

GLW Storing Systems GmbH - Würzburg, Germany

Diamonds are a laser scientist’s new best friend - Once a James Bond fantasy, diamond-based lasers are now becoming a reality